When you’re tasked with designing a lightweight aircraft component or a high-performance bike frame, the choice of material can make or break your project. Enter 7075 aluminum—a standout member of the 7000 series and a favorite among engineers for its remarkable strength-to-weight ratio. But what really sets the 7075 alloy apart? Let’s break down its identity and see why density is far more than just a number on a spec sheet.

What makes 7075 so compelling? It’s not just about raw strength. The material’s aluminum density—specifically, its mass per unit volume—directly shapes how much weight you can save while still achieving the required structural integrity. In weight-sensitive and high-stress applications, this balance is crucial.

"7075 aluminum is often dubbed the 'aircraft aluminum'—a nickname earned for its unmatched combination of high strength and low density, empowering engineers to design lighter, stronger, and more efficient components."

Imagine designing a fuselage frame or a precision-machined robotic arm. If you overlook density, you risk overshooting weight targets or underestimating performance. That’s why understanding the specific density of 7075 alloy—and how it compares to other materials—gives you a powerful edge in engineering design.

In the chapters ahead, you’ll see how the density of 7075 aluminum underpins its real-world applications and why it remains a top choice for demanding engineering projects.

When you pick up two metal parts of the same size—one feeling much heavier than the other—you’re experiencing the impact of density firsthand. But what is aluminium density, exactly? In engineering terms, density is simply the amount of mass packed into a given volume. It’s the property that tells you, for any material, how much it weighs for its size. This single number becomes a deciding factor in countless design decisions, from aircraft wings to automotive panels.

For example, if you have a solid block that weighs 5,400 kg and occupies a volume of 2 m³, the density is calculated as:

This value matches the typical density of aluminum kg/m3—a useful reference point for engineers verifying materials or estimating part weights.

Imagine you’re designing a lightweight drone frame or a high-speed train panel. The density of aluminum alloy you choose will directly affect the final product’s weight, inertia, and how much force it takes to move or stop it. Lower density means lighter components, which is essential for applications where every ounce counts.

For reference, the aluminum density in lb/in3 is approximately 0.1 for pure aluminum, but this can vary slightly depending on the alloy and processing methods.

Understanding the density of aluminium in lb in3 or kg/m³ is more than an academic exercise—it’s a fundamental step in engineering smarter, lighter, and more efficient products.

In the next section, we’ll zoom in on the specific density values for 7075 aluminum and see how this property empowers high-performance designs.

When you’re engineering parts for weight-sensitive applications, knowing the exact 7075 aluminum density is crucial. So, what is the number you should rely on? The density of 7075 aluminum is approximately 2.81 g/cm³ (or 0.102 lb/in³). This places it just above pure aluminum, which typically has a density of 2.70 g/cm³. In practical terms, this means that for every cubic centimeter of 7075, you can expect it to weigh about 2.81 grams—a figure that guides engineers in everything from weight calculations to material selection.

But what about the effect of different tempers, such as 7075-T6 or 7075-T7351? Here’s where a common misconception trips up even experienced designers.

It’s easy to assume that since heat treatments like T6 (which boosts strength) or T7351 (which improves stress corrosion resistance) dramatically change mechanical properties, they might also affect the al 7075 density. In reality, the density of aluminium 7075 remains virtually unchanged across tempers. That’s because heat treatment alters the internal structure—improving strength, hardness, and fatigue resistance—but does not significantly change the mass or volume of the alloy.

Think of it this way: no matter which temper you select, the density of 7075 aluminum you calculate for your design remains consistent. This reliability makes it easier to estimate weights and ensure that your final product meets strict performance criteria—whether you’re building an aircraft wing spar or a high-stress mechanical component.

Imagine you’re finalizing the design for a lightweight frame. If you’re switching between 7075-t6 and 7075-t7351 to optimize for strength or fatigue life, you won’t need to recalculate the density each time. This consistency streamlines the engineering process and reduces the risk of costly errors in weight-sensitive applications.

Want to dive even deeper into the nuances of aluminum alloy densities? Check out our related blog for a comprehensive guide to values and alloys: Aluminum Density: Your Essential Guide to Values & Alloys.

Now that you know the specifics of 7075 aluminum density, let’s see how it compares to other popular engineering materials—and why those differences matter for your next project.

When you’re deciding between metals for your next engineering project, it’s easy to get lost in a sea of numbers. But here’s a simple truth: density is a foundational property that shapes everything from part weight to structural performance. So, how does 7075 aluminum measure up against other popular engineering materials like 6061 aluminum, 5052 aluminum, Grade 5 titanium, and 304 stainless steel? Let’s break it down with a comparative table, then walk through what these numbers mean in real-world applications.

| Material | Density (g/cm³) | Density (kg/m³) | Density (lb/in³) |

|---|---|---|---|

| 7075 Aluminum | 2.81 | 2,810 | 0.102 |

| 6061 Aluminum | 2.70 | 2,700 | 0.0975 |

| 5052 Aluminum | 2.68 | 2,680 | 0.097 |

| Grade 5 Titanium (Ti-6Al-4V) | 4.43 | 4,430 | 0.160 |

| 304 Stainless Steel | 7.93 | 7,930 | 0.286 |

At first glance, the differences may seem small, but they have a huge impact on performance, cost, and manufacturability. Let’s walk through the key comparisons:

When you compare 6061 vs 7075, or 7075 to steel, remember: density is more than a number—it’s the gateway to lighter, stronger, and more efficient designs.

Next, we’ll see how these density differences play out in a real-world case study: aerospace engineering, where every gram counts and material choice is mission-critical.

Imagine sitting inside a modern jetliner, cruising at 35,000 feet. Have you ever wondered what keeps such a massive airplane both strong and remarkably light? The answer often lies in the clever use of advanced materials—most notably, 7075 aircraft aluminum. But what makes this alloy so indispensable in aerospace engineering? It all comes down to density.

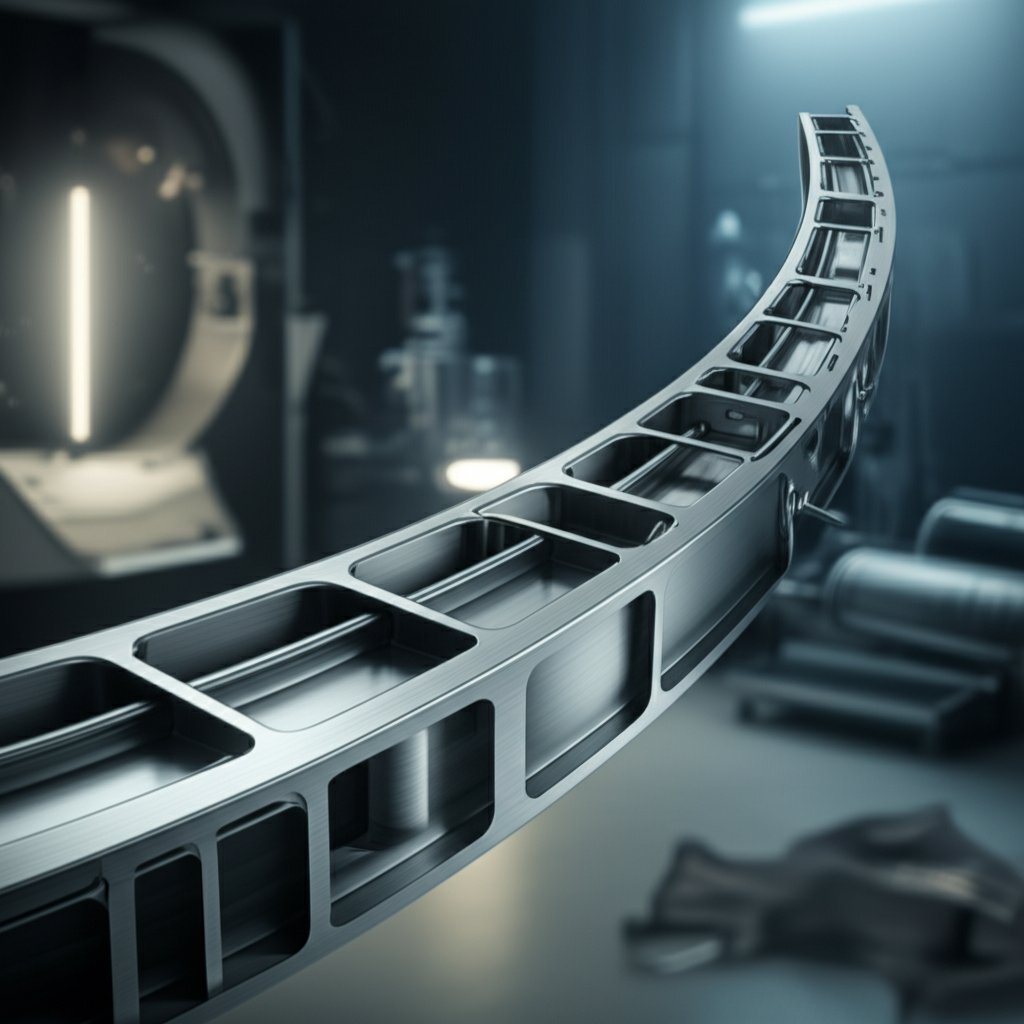

In aviation, every gram counts. Lighter aircraft consume less fuel, carry more cargo, and offer better maneuverability. Here’s where 7075 aluminum tube and sheet products become the backbone of critical structures:

Let’s break down the practical advantages of choosing 7075 t6 aircraft aluminum for aerospace structures:

Consider the wing spar of a modern passenger jet. Traditionally, steel would provide the required strength, but its high density would dramatically increase overall aircraft weight. By switching to a 7075 aluminum tube or extrusion, engineers achieve:

As a result, airlines benefit from lower fuel bills, while passengers enjoy safer and more efficient travel.

It’s no coincidence that 7075 aircraft aluminum is still the go-to material for everything from commercial jets to military fighters and even spacecraft. Its density strikes a perfect balance between weight savings and mechanical integrity—qualities that are non-negotiable in flight-critical applications.

Selecting the right material isn’t just about numbers on a datasheet. In aerospace, the low density of 7075 aluminum tube translates directly into real-world advantages: longer range, higher payload, and greater safety margins.

In the next section, we’ll explore how density shapes not just the design, but also the manufacturing and logistics of advanced aerospace components—proving that material choice impacts every stage of production.

When you’re tasked with optimizing a part for both strength and weight, the density of your material becomes a silent but powerful design partner. Sounds complex? Let’s break it down: how does the relatively low density of 7075 aluminum—about 2.81 g/cm³—directly impact your decisions from CAD modeling to the factory floor?

Imagine you need to create a component that resists bending or buckling under load—say, a structural bracket or a drone arm. If you use a denser material like steel, increasing thickness quickly adds weight, which may push your design over target mass limits. But with 7075 aluminum, you can boost section size for rigidity while still staying within strict weight budgets. This is where the real value of 7075 aluminum properties shines:

Density doesn’t just affect how you draw your parts—it also shapes what happens in the shop. Here’s where 7075 material properties offer tangible production benefits:

These benefits stem from the core 7075 composition, which balances high performance with manageable weight and processability.

Consider the manufacturing of an aircraft seat frame. Using 7075 aluminum material properties, engineers can design thicker, more impact-resistant sections compared to steel, yet keep the seat light enough to meet strict airline regulations. In automotive racing, suspension arms made from 7075 can be beefed up for durability—without sending the car’s total weight soaring.

These trade-offs are only possible because of the unique balance of 7075 properties: high strength, low density, and excellent machinability.

Ever considered the cumulative impact of density on your project’s bottom line? With 7075, you’ll notice:

Ultimately, understanding the influence of density on design and manufacturing isn’t just academic. It’s a practical, daily advantage that can make your next project more efficient, cost-effective, and innovative.

The low density of 7075 aluminum empowers you to rethink what’s possible—enabling stronger, lighter, and smarter designs from the drawing board to the assembly line.

Next, we’ll look at how these material efficiencies translate into real-world savings—beyond just price-per-pound—so you can make the smartest choice for your next engineering challenge.

When you’re evaluating materials for your next engineering project, it’s tempting to focus on the aluminum cost per pound or kilogram. After all, that number is right there on the quote sheet. But is it really telling you the whole story? Imagine two sheets of metal—one heavier, one lighter, but both priced the same per pound. Which one will truly save you money when it comes time to produce hundreds or thousands of parts? The answer lies in understanding how density affects your bottom line—especially with high-performance alloys like material 7075.

Here’s where many engineers and buyers get tripped up: aluminum sheeting and other raw materials are sold by weight, but your parts are made to specific dimensions—meaning, by volume. If you only look at price-per-pound, you might miss out on the real cost advantages offered by lower-density materials. As explained in industry best practices (reference):

For example, if material 7075 is slightly pricier per pound than another alloy, but its density is lower, you may end up producing more finished parts per dollar spent. This is crucial for applications where the number of components or the total volume of material used is a key factor—think aerospace brackets, automotive panels, or precision aluminum sheeting for electronics.

Still not convinced? Let’s dig deeper. The true cost of a material isn’t just its purchase price. The Total Cost of Ownership (TCO) includes:

As highlighted in advanced manufacturing references, focusing solely on the upfront price can mask ongoing operational savings. Over time, the benefits of lower density—like reduced shipping, easier handling, and more parts per batch—add up to significant cost advantages.

Let’s say you’re sourcing aluminum sheeting for a run of lightweight drone frames. If you compare only the price per pound, you might pick a cheaper but denser alloy. But when you factor in density, you’ll see that material 7075 allows you to produce more frames per unit weight, offsetting the higher initial price and lowering your true cost per part.

"Relying on price per pound alone may lead to poor choices and costly mistakes. Always factor in density and total cost of ownership when selecting engineering materials."

By understanding the real cost implications of 7075 aluminum density, you’ll make smarter decisions that benefit your project’s performance and your organization’s bottom line. Next, we’ll wrap up with practical advice on sourcing high-quality 7075 aluminum to ensure you get all the benefits this advanced alloy has to offer.

Imagine you’ve spent weeks perfecting an aerospace bracket or a precision automotive part, only to discover that the material you sourced doesn’t meet your project’s strength or weight requirements. Sounds frustrating? That’s why, when it comes to aluminium 7075, sourcing from a reputable manufacturer isn’t just a suggestion—it’s a necessity.

When you’re searching for a supplier, don’t just look at price—ask these essential questions:

| Checklist | Why It Matters |

|---|---|

| Does the supplier offer ASTM/ISO certification? | Guarantees material meets global quality standards and consistent 7075 yield strength. |

| Can they provide traceability for each batch? | Ensures every piece of aluminium 7075 can be tracked back to its source. |

| Do they have experience with high-spec applications? | Proven expertise means fewer surprises in demanding sectors like aerospace and automotive. |

| Are density and mechanical properties regularly tested? | Confirms your material will deliver the expected 7075 aluminum yield strength and density every time. |

For projects where performance and reliability are non-negotiable, it pays to work with a specialist. Shengxin, a leading aluminum profile manufacturer in China, is renowned for its commitment to quality and advanced production capabilities. With a focus on alloys like al 7075, Shengxin ensures that every batch meets stringent density and strength specifications—so you can trust your material 7075 t6 aluminum to perform in the most demanding environments.

Choosing the right supplier is more than a procurement decision—it’s the foundation for achieving the full potential of 7075 aluminum density in your next engineering breakthrough. For more on sourcing high-quality aluminum profiles, visit Shengxin Aluminium.

7075 aluminum has a density of approximately 2.81 g/cm³ (0.102 lb/in³), making it ideal for applications that require both high strength and reduced weight.

7075 aluminum is slightly denser than 6061 but far less dense than stainless steel. This means 7075 offers a superior strength-to-weight ratio, making it preferable for aerospace and performance applications where minimizing weight is crucial.

No, the temper or heat treatment of 7075 aluminum (like T6 or T7351) does not significantly change its density. These treatments alter mechanical properties such as strength, but the fundamental density remains consistent.

Density directly impacts the final weight, structural efficiency, and cost-effectiveness of a component. For weight-sensitive designs, 7075 aluminum's low density allows for strong, lightweight parts that improve performance and reduce operational costs.

Always choose suppliers who provide full certification and traceability, such as ASTM or ISO standards. This ensures the 7075 aluminum meets required density and strength specifications, which is critical for safety and reliability in demanding applications.

un service en ligne

un service en ligne 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360