When you hear the term “aluminum plate,” what comes to mind? Maybe you picture a sturdy panel supporting a bridge, or perhaps a sleek sheet forming part of a modern vehicle. Sounds complex? The truth is, aluminum plate is everywhere—playing a silent but vital role in countless industries and even DIY projects.

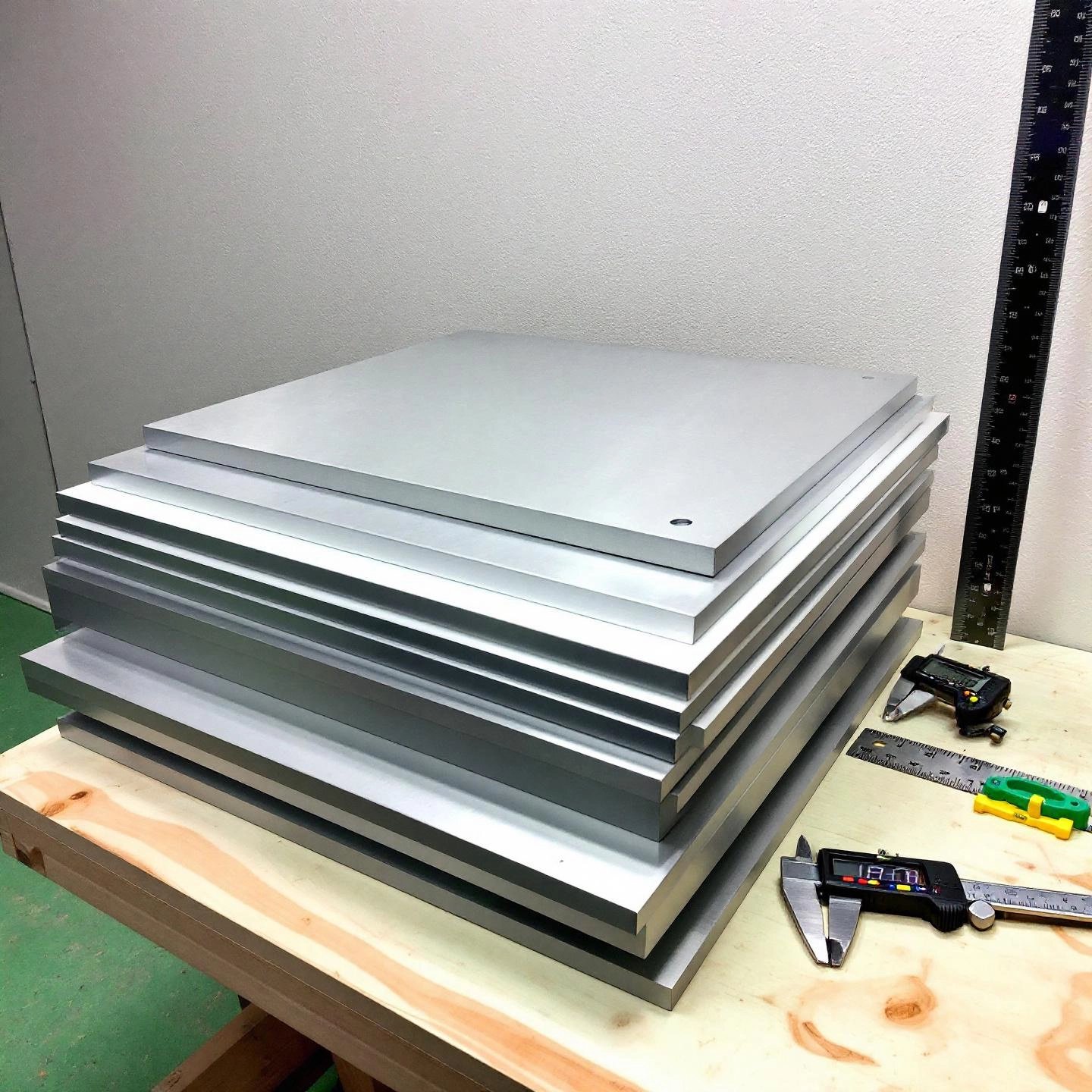

So, what exactly is an aluminum plate? In the simplest terms, it’s a flat-rolled product made from pure aluminum or its alloys, with a thickness that sets it apart from sheet metal. While aluminum sheets are typically less than 0.25 inches thick, plates are 0.25 inches (6.35 mm) or more, making them the go-to choice for heavy-duty applications where strength and durability matter most. In some regions, anything above 6 mm is considered a plate, but the core idea remains: plates are thicker, stronger, and built for demanding tasks.

Why is aluminum plate so popular? Let’s break down its standout qualities:

From the skin of spacecraft and the armor of military vehicles to ship decks, truck beds, and even intricate DIY creations, aluminum plate adapts to almost any challenge. You’ll notice it in industries like aerospace, automotive, construction, marine, and electronics—wherever performance, longevity, and efficiency are top priorities.

This guide is designed for anyone searching for the right aluminum plate for sale—whether you’re an engineer planning a major build, a manufacturer seeking reliable materials, or a hobbyist tackling your next project. We’ll walk you through everything you need to know: how to choose the right type, thickness, and grade; how to compare patterns and finishes; and practical tips for sourcing quality plates. By the end, you’ll have the confidence to select the aluminum plate that perfectly fits your needs.

Ever wondered what gives some floors, truck beds, or industrial walkways that distinctive, rugged look—and why they’re so safe to walk on? That’s the magic of aluminum diamond plate. But this material is about far more than good looks. Let’s break down what makes it unique, and why it’s a staple in both industrial and creative projects.

Picture a shiny sheet of aluminum with a pattern of raised diamonds on one side and a smooth finish on the other. That’s aluminum diamond plate—also called tread plate or checker plate. The diamond-shaped ridges are pressed into the metal during manufacturing, creating a textured surface that’s instantly recognizable. The depth and size of these diamonds can vary, offering different levels of grip and visual impact.

The raised diamond pattern is more than just a design choice. Here’s what it brings to the table:

So, where do you see aluminum diamond plate in action? Its blend of safety, strength, and style makes it a go-to choice in a surprising range of settings. Here are some of the most popular diamond plate uses:

Whether you’re looking to improve safety in a busy warehouse, add durability to a vehicle, or bring an industrial touch to home décor, aluminum diamond plate offers a practical, attractive solution. Its unique properties make it one of the most versatile materials available for both functional and creative projects.

Next, we’ll explore how tread plate and checker plate patterns differ—helping you choose the right texture for your specific needs.

Ever found yourself confused by the terms tread plate and checker plate? You’re not alone. These names are often used interchangeably, but they actually refer to different things. So, when you’re sourcing materials for a project—or just trying to make sense of a product catalog—knowing the difference can save you time, money, and headaches.

Imagine you’re walking through a busy factory or stepping into a truck bed. The textured metal under your feet is there for a reason: traction and safety. But what do you call it? Here’s where things get interesting:

In short, all checker plates are tread plates, but not all tread plates are checker plates. If that sounds a bit like a riddle, think of it this way: tread plate is the category, checker plate is a style within it.

Patterns aren’t just about looks—they affect grip, cleaning, and even the cost of your project. Let’s break down the most popular designs you’ll encounter when shopping for aluminum checker plate or other tread plates.

| Pattern Name | Visual Description | Common Terminology | Typical Applications |

|---|---|---|---|

| Diamond | Raised, repeating diamonds (small rhombuses) in a grid | Diamond Plate, Checker Plate, Tread Plate | Factory floors, truck beds, stairs, walkways, ramps |

| Five-Bar | Five parallel bars in a pattern, each set at an angle (60-80°) to the others | Five-Bar Plate, Willow Leaf Plate, Checker Plate | Platforms, vehicle floors, construction, anti-slip surfaces |

| Lentil/Bean | Oval or bean-shaped raised bumps, evenly spaced | Lentil Plate, Patterned Plate | Vehicle interiors, cold storage floors, workshops |

| Orange Peel | Surface resembles the texture of an orange peel | Orange Peel Plate, Patterned Plate | Refrigerators, home appliances, decorative panels |

| Spherical | Small, round, pearl-like raised bumps | Spherical Plate, Semi-Spherical Plate | Packaging, decorative applications, areas needing extra strength |

Choosing the right pattern isn’t just about style. Here’s what to consider:

Material choice also matters. Aluminum checker plate is lightweight, corrosion-resistant, and easy to work with—perfect for projects where reducing weight and maintenance is crucial. Steel tread plates, on the other hand, offer extra strength but may require coatings to prevent rust.

So, next time you’re comparing tread plate vs checker plate, think about where and how it will be used. The right pattern and material can make all the difference in safety, durability, and even the look of your finished project.

Ready to choose the right thickness for your application? Up next, we’ll guide you through selecting the ideal plate thickness for strength, performance, and cost-effectiveness.

When you’re planning a project—whether it’s a custom machine bed, a marine platform, or even a heavy-duty cabinet—choosing the right aluminum plate thickness can feel overwhelming. Too thin, and you risk bending or failure. Too thick, and you might add unnecessary weight, waste money, or face machining headaches. So, how do you strike the perfect balance?

Imagine you’re building a ramp for a loading dock. If you use a plate that’s too thin, it could flex under weight, causing safety issues. But if you go overboard with a thick plate, the ramp becomes heavy, expensive, and tough to work with. Thickness isn’t just a number—it’s the key to your project’s strength, durability, and cost-effectiveness.

So, how do you decide? Start by asking these questions:

| Thickness (inches) | Approx. mm | Common Uses |

|---|---|---|

| 0.25" | 6.35 mm | Door panels, small platforms, cabinetry, light-duty covers |

| 0.375" | 9.5 mm | Transportation chassis, framing, moderate-duty platforms |

| 0.5" | 12.7 mm | Engine parts, marine flooring, machine beds, heavy-duty structures |

| 0.75"+ | 19 mm+ | Industrial tanks, base plates, aerospace, military armor |

There’s no one-size-fits-all answer. Thicker plates boost aluminum plate strength, but they also add weight and cost. Thinner plates are lighter and cheaper but may not stand up to heavy loads. The right choice depends on your unique project needs—and sometimes, a little expert guidance goes a long way.

No matter what thickness you choose, accuracy matters. Always measure at multiple points using a calibrated caliper or micrometer to ensure your plate meets industry standards. Confirm thickness before fabrication to avoid costly mistakes, and specify your requirements—including alloy, temper, and finish—when ordering.

Looking for reliability? Shengxin Aluminum delivers plates with precise thickness control and structural integrity, tailored for demanding industrial and custom applications. Their advanced production lines and strict quality standards ensure you get exactly what your project requires—every time.

Now that you know how to select the right thickness, let’s dive deeper into the most popular sizes—like 1/4 and 1/2 inch plates—and see where they shine in real-world projects.

When you’re narrowing down your options for an aluminum plate, two thicknesses stand out from the rest: 1/4 inch and 1/2 inch. But how do you know which is right for your project? Let’s break down what makes each thickness unique, and where you’ll find them in action—from construction sites to high-tech manufacturing floors.

Imagine you’re building a sturdy platform, fabricating a machine part, or reinforcing a boat hull. The thickness of your aluminum plate determines not just its strength, but also its weight, workability, and cost. That’s why 1/4 inch and 1/2 inch plates have become industry standards—they hit the sweet spot between performance and practicality for a wide range of needs.

Think of 1/4 inch aluminum plate as the “all-rounder” in the world of metal fabrication. It offers enough strength for structural support, yet remains light and easy to handle. This makes it a favorite for medium-duty jobs where both durability and flexibility matter.

Beyond its versatility, 1/4 inch aluminum plate is also easy to cut, bend, and weld, making it a great choice for both professional and DIY projects. If you need a durable material that won’t weigh you down, this thickness is a reliable go-to.

When your project calls for maximum strength and stability, 1/2 inch aluminum plate is up to the challenge. Its increased thickness makes it suitable for heavy loads, high-impact environments, and applications where structural integrity is non-negotiable.

Despite its thickness, 1/2 inch aluminum plate remains lighter than steel, offering a high strength-to-weight ratio and natural corrosion resistance. It’s also recyclable, making it a sustainable choice for demanding projects.

Not sure which thickness fits your needs? Ask yourself:

For most medium-duty tasks, 1/4 inch aluminum plate offers a great balance of strength and workability. For high-stress, structural, or outdoor applications, 1/2 inch plate delivers the extra durability you need.

Now that you have a clearer picture of these two popular thicknesses, let’s look at how standard sheet sizes—like the widely used 4x8 foot plate—can further streamline your project planning and sourcing.

When you start searching for an aluminum plate for your next project, you’ll notice one size keeps popping up: 4 feet by 8 feet, or 48" x 96". But why is the 4x8 aluminum plate so common, and what makes it the go-to choice across industries?

Imagine you’re planning a project—maybe cladding a wall, building a truck bed, or fabricating a machine enclosure. You want a material that’s easy to source, simple to transport, and efficient to work with. That’s where the aluminum sheet 4x8 shines. This size is recognized globally and has become the industry benchmark for good reason:

While the 4x8 format covers a vast range of needs, sometimes your project demands something different—maybe a unique shape, extra-long panel, or a non-standard thickness. Most suppliers can cut or fabricate custom sizes, but it’s important to weigh the pros and cons:

| Standard 4x8 Plate | Custom Sizing |

|---|---|

| Lower cost per square foot | Higher price due to extra handling and waste |

| Faster delivery, always in stock | Longer lead times, possible minimum order |

| Easy to plan, quote, and estimate | Requires careful measurement and custom quoting |

| Fits standard fabrication and installation tools | May require special equipment or extra labor |

In most cases, starting with a 4x8 aluminum plate saves time and money—especially for construction, transportation, or manufacturing projects where efficiency and predictability matter. But if your design calls for something special, custom sizing remains an option, just with added cost and planning.

Up next, let’s take a closer look at the alloys behind these plates—starting with the ever-popular 6061 aluminum and why it’s a top choice for both standard and custom applications.

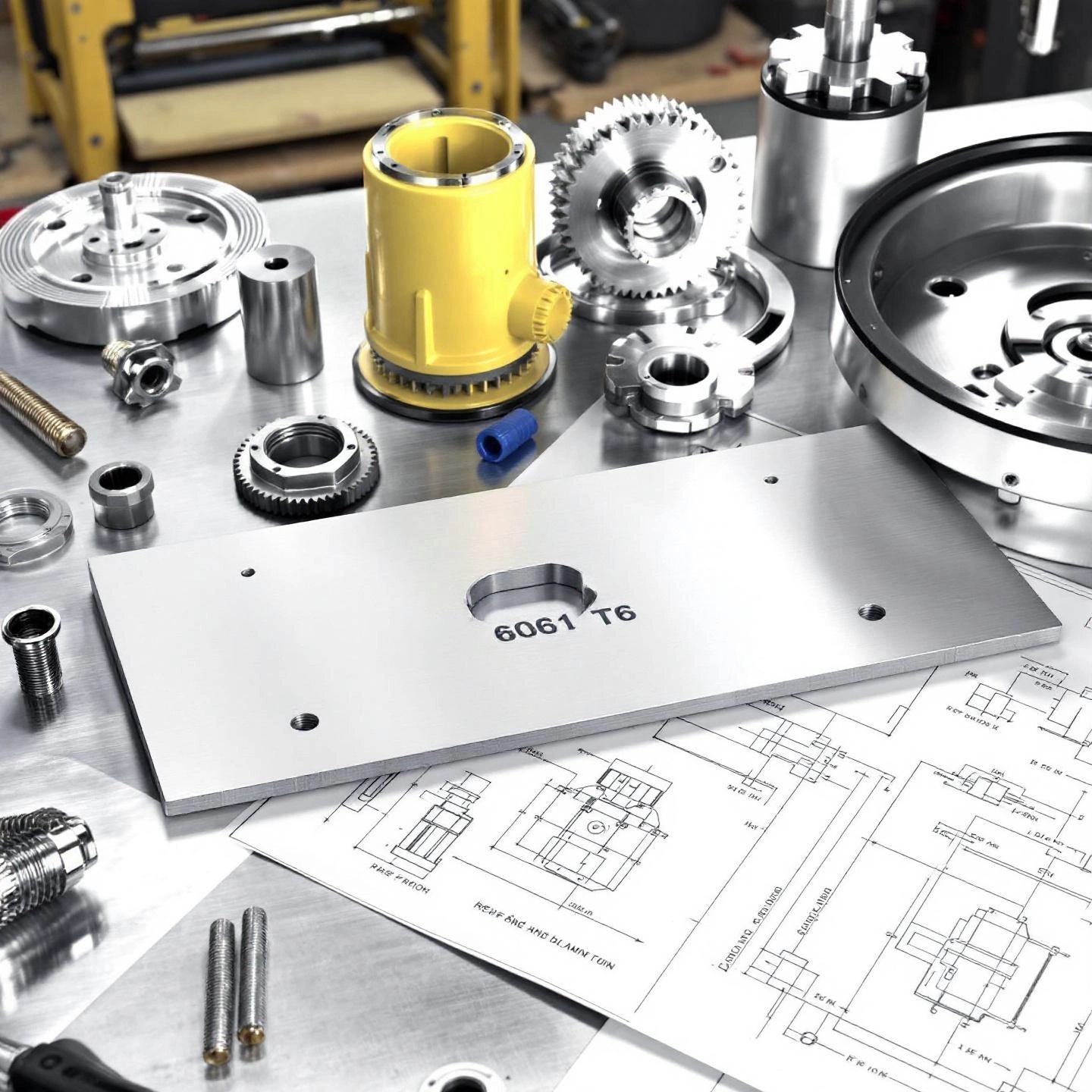

When you’re choosing an aluminum plate for your project, you might wonder: What makes one alloy more suitable than another? Enter 6061 aluminum plate—a material that’s become the backbone of industries ranging from aerospace to construction. But what’s behind its popularity? Let’s break it down in simple terms, so you know exactly why 6061 is often the first choice for demanding tasks.

Imagine an alloy that combines lightness with impressive strength, resists rust and corrosion, and can be shaped, welded, or machined to fit just about any design. That’s 6061. It’s a precipitation-hardened aluminum alloy, which means it’s strengthened through a special heat treatment process. Its two main alloying elements are magnesium and silicon, giving it a unique balance of properties that make it stand out from other grades.

You’ll often see 6061 offered as 6061 T6 aluminum plate. What does the “T6” mean? It refers to a specific tempering process that maximizes the alloy’s strength and durability. Here’s how it works: the plate is solution heat-treated, then artificially aged—essentially, it’s carefully heated and cooled to lock in superior mechanical properties. The result? A plate that’s strong, stable, and ready for tough jobs.

Why do engineers and fabricators keep coming back to 6061? Let’s look at its standout features:

Still not sure if it’s right for your needs? Consider these typical applications for 6061 and 6061 T6 aluminum plate:

Imagine building a lightweight bridge, crafting a custom car part, or fabricating a corrosion-resistant boat deck—6061 is likely the alloy making it possible. Its versatility, reliability, and ease of use have made it the industry’s go-to choice for both standard and custom aluminum plate projects.

Now that you know why 6061 aluminum plate is so widely trusted, let’s move on to the practical side: What should you check before making a purchase? The next section will walk you through a buyer’s checklist so you can shop with confidence.

When you’re ready to buy aluminum plate—whether for a major industrial project or a personal DIY build—the sheer number of options can feel overwhelming. How do you make sure you’re choosing the right material for your needs, with no costly surprises down the road? Let’s break it down with a simple, step-by-step checklist that covers all the essentials, from technical specs to supplier reliability.

Imagine you’re planning a project: you want durability, a perfect fit, and the right look. Missing even one detail could mean delays or extra expenses. Here’s a structured approach to help you confidently evaluate any aluminum plate for sale:

| Factor | What to Consider | Why It Matters |

|---|---|---|

| Grade (Alloy Series) |

|

Each alloy offers a unique balance of strength, formability, and corrosion resistance—matching the alloy to your application ensures performance and longevity. |

| Temper |

|

Temper determines how the plate handles stress, machining, and forming—pick the right one for your fabrication process. |

| Pattern |

|

Patterns add grip, rigidity, and sometimes visual appeal—vital for flooring, ramps, or decorative applications. |

| Thickness |

|

Too thin, and you risk failure; too thick, and you add cost and weight. Always verify with a caliper or micrometer before fabrication. |

| Dimensions |

|

Choosing the right size minimizes waste and speeds up installation. |

| Finish |

|

Finish affects appearance, corrosion resistance, and suitability for certain environments. |

Imagine needing a custom alloy, a unique pattern, or tight tolerances for your project. Not every supplier can deliver—especially at scale or with strict quality control. This is where vertically integrated manufacturers like Shengxin Aluminum stand out. With advanced production lines, in-house testing, and a full range of finishing and fabrication options, Shengxin ensures each plate meets your exact requirements—whether for aerospace, transportation, marine, or architectural applications.

Ready to take the next step? With this checklist in hand, you’re prepared to evaluate any aluminum plate for sale and make an informed, confident purchase. Next, let’s explore the best ways to source your material—whether from local suppliers or trusted online retailers.

When you’re ready to source material for your next project, the first question is often: “Where can I find the right aluminum plate near me, or should I look online?” The answer depends on your needs, budget, and timeline. Let’s walk through practical steps to help you decide—and ensure you get the best quality and value, whether you’re buying a single sheet or outfitting an entire production line.

Imagine you need a specific grade or want to inspect the plate before purchasing. Local distributors and metal service centers are often the first stop. By searching terms like aluminum plate near me, you’ll discover a range of businesses—from large regional distributors to specialty shops. Here’s what you might find:

According to Thomasnet, local distributors often stock a wide range of alloys, patterns, and thicknesses, with custom sizes available for special orders. Some even provide value-added services like anodizing, painting, or packaging. For one-off or small quantity needs, you might also consider visiting local scrap dealers—just be sure to check for clear markings and certifications if your application requires them (Practical Machinist).

If you’re looking for a broader selection, specialty alloys, or simply the convenience of ordering from your desk, online retailers are a powerful option. Whether you’re searching for bulk orders, hard-to-find alloys, or custom cuts, the online marketplace can connect you with suppliers across the country.

However, it’s important to factor in shipping costs, lead times, and minimum order requirements, especially for large or heavy plates. For custom or urgent orders, always confirm availability and delivery dates before purchasing.

| Option | Pros | Cons |

|---|---|---|

| Local Suppliers |

|

|

| Online Retailers |

|

|

Whether you choose a local distributor or an online retailer, knowing where to buy aluminum plate—and what to look for—can make all the difference in your project’s success. Up next: we’ll wrap up with a summary of key steps to make your buying decision even easier.

When it comes to selecting the best aluminum plate for your needs, the process can seem daunting. But with the right approach, you’ll find it’s all about asking the right questions and following a few clear steps. Still unsure where to start? Imagine you’re planning a new project—maybe a custom trailer, a marine platform, or an industrial upgrade. What should you check first?

Let’s break down the essentials into a practical, easy-to-follow checklist. Each decision you make—from the alloy to the finish—will directly impact your project’s performance, longevity, and cost-effectiveness.

| Step | What to Consider | Why It Matters |

|---|---|---|

| 1. Identify Your Application | Is it for structural support, decoration, marine use, or machinery? | Matching the plate’s properties to your use ensures safety and durability. |

| 2. Select the Pattern | Diamond, five-bar, lentil, or other textures? | Patterns add grip, rigidity, and sometimes a unique visual flair—crucial for safety and aesthetics. |

| 3. Determine Thickness | What loads will the plate bear? Will it be exposed to wear or impact? | Choosing the right thickness balances strength, weight, and cost—avoiding over- or under-engineering. |

| 4. Choose the Alloy and Grade | 6061 for versatility, 5000 series for corrosion resistance, 3000 for economy, etc. | Each alloy offers unique benefits for strength, formability, and resistance to the elements. |

| 5. Decide on Dimensions | Standard 4x8 sheets, custom sizes, or pre-cut parts? | Standard sizes are cost-effective and easy to source; custom cuts reduce waste for unique designs. |

| 6. Specify the Finish | Mill, anodized, or polished? | The right finish improves corrosion resistance, appearance, and long-term performance. |

By following this aluminum plate buyer's guide, you’re not just checking boxes—you’re ensuring your project’s success. Each step narrows the field, helping you avoid costly mistakes and select a plate that fits perfectly, performs reliably, and looks great for years to come.

And remember, the supplier you choose makes a difference. Imagine working with a manufacturer who understands your needs, offers technical support, and delivers consistent quality. That’s where vertically integrated experts like Shengxin Aluminum stand out. With advanced production capabilities, rigorous quality control, and a full range of customization options, Shengxin ensures every plate meets your exact requirements—whether for aerospace, marine, construction, or creative projects.

Ready to take the next step? Use this guide as your roadmap, and don’t hesitate to reach out for expert advice or a custom solution. With the right knowledge and a trusted partner, you’ll always find the best aluminum plate for your project—no matter how demanding the application.

Aluminum plate is thicker than sheet metal—typically 0.25 inches (6.35 mm) or more—making it ideal for heavy-duty applications requiring greater strength and durability. Sheets are thinner and better suited for lighter projects.

Aluminum diamond plate is widely used for truck bed liners, industrial flooring, ramps, marine decks, wall coverings, and decorative elements due to its slip-resistant pattern, strength, and corrosion resistance.

Select thickness based on the load and environment. Lighter duties often use 1/4 inch plates, while heavy loads or structural applications require 1/2 inch or more. Always consider weight, fabrication needs, and cost for your specific project.

6061 aluminum plate offers an outstanding balance of strength, corrosion resistance, weldability, and machinability, especially in the T6 temper. It's a top choice for aerospace, automotive, marine, and structural uses.

You can purchase aluminum plate from local metal suppliers for hands-on service or from online retailers for a wider selection and convenient delivery. Compare inventory, customization options, and lead times to find the best fit for your needs.

un service en ligne

un service en ligne 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360