Aluminum strips are a versatile material used extensively across a range of industries, from construction to automotive and electronics. Their popularity stems from their unique properties, which include lightweight, strength, and excellent corrosion resistance. But what exactly are aluminum strips, and why are they so valued in both industrial and DIY applications?

At their core, aluminum strips are thin, flat pieces of aluminum that can vary in width and thickness, depending on their intended use. These strips are typically produced through a process of rolling aluminum into thin sheets, which are then cut to the desired size. The composition of aluminum strips can vary significantly, ranging from pure aluminum to various alloys that enhance specific properties such as strength and resistance to wear.

One of the key reasons aluminum strips are favored in construction and restoration projects is their exceptional versatility. They can be used for structural support, decorative trim, and even in insulation applications. Their high strength-to-weight ratio makes them an ideal choice for projects where reducing weight without compromising durability is crucial. For instance, in the automotive industry, aluminum strips are increasingly used to make vehicles lighter, thereby improving fuel efficiency and reducing emissions (source) .

Moreover, aluminum strips are known for their excellent thermal conductivity, which makes them suitable for applications that require heat dissipation, such as in HVAC systems or electronic devices (source) . Their corrosion resistance also ensures longevity even in harsh environments, making them a preferred choice for outdoor construction and restoration projects.

In summary, aluminum strips offer a combination of strength, lightweight, and resistance to environmental factors, making them indispensable in both industrial and DIY settings. Whether used in large-scale construction projects or small home renovations, their adaptability and robust properties ensure they remain a staple material in many applications.

Aluminum strips are renowned for their remarkable properties, which make them a preferred choice across various industries. But what are the fundamental characteristics that set them apart? Let's delve into the essential attributes of aluminum strips, including their thermal conductivity, corrosion resistance, and the impact of different alloy compositions on their strength and durability.

One of the standout features of aluminum strips is their exceptional thermal conductivity. In fact, the thermal conductivity of aluminum is approximately three times greater than that of steel, making it an excellent material for applications requiring efficient heat dissipation. This makes aluminum strips ideal for use in heat exchangers, electronics, and even cooking utensils where rapid heat transfer is beneficial.

Equally important is the corrosion resistance of aluminum. When exposed to air, aluminum naturally forms a thin oxide layer that protects it from further oxidation. This inherent corrosion resistance makes aluminum strips suitable for outdoor applications and harsh environments, where they can withstand exposure to moisture and other corrosive elements without degrading over time.

Aluminum strips are also celebrated for their ease of fabrication. They can be easily rolled, extruded, or machined into various shapes and sizes, offering flexibility in manufacturing processes. This malleability allows them to be tailored to specific project requirements, whether in construction, automotive, or electronics.

The strength and durability of aluminum strips can be significantly enhanced by alloying. By combining aluminum with elements like copper, magnesium, or silicon, manufacturers can produce alloys that offer increased strength and specific properties tailored to particular applications. For instance, certain alloys are designed to improve tensile strength, making them suitable for structural components, while others focus on enhancing corrosion resistance for marine environments.

In summary, the fundamental characteristics of aluminum strips—thermal conductivity, corrosion resistance, and adaptability through alloying—make them an indispensable material in modern engineering and design. These properties not only enhance their functional performance but also ensure their continued relevance in a wide range of applications, from everyday household items to advanced industrial systems.

When embarking on a DIY project, selecting the right materials is crucial, and aluminum strips offer a versatile solution for a variety of applications. Whether you're looking to enhance your home with new trims, tackle a decorative project, or engage in a more substantial renovation, understanding the different types and sizes of aluminum strips can make all the difference.

Aluminum strips come in a range of widths and thicknesses, making them suitable for diverse tasks. For instance, 1 inch wide aluminum strips are particularly popular for their balance of strength and flexibility, making them ideal for creating sleek, modern trims or edging for countertops and cabinetry. Their manageable size allows for easy handling and installation, even for novice DIY enthusiasts.

Thicker aluminum strips, such as those measuring up to 1/8 inch in thickness, are perfect for projects that require more robust support, such as structural reinforcements or creating durable frames. These thicker strips provide the necessary strength while still being lightweight enough for easy manipulation.

Finding the right aluminum strips for your project is as easy as visiting your local home improvement store. Retailers like Home Depot and Lowes offer a wide selection of aluminum strips, including various dimensions to suit your needs. For example, Home Depot stocks a variety of options, from the commonly sought-after 1 inch wide strips to broader and thicker alternatives, ensuring that you can find the perfect fit for your project.

Additionally, these retailers often provide online shopping options, allowing you to browse and purchase from the comfort of your home. This convenience is especially beneficial if you require specific sizes or need to compare different products before making a decision.

In conclusion, the versatility of aluminum strips makes them an excellent choice for any home project. By selecting the right dimensions and purchasing from reliable sources like Home Depot or Lowes, you can ensure that your DIY endeavors are both successful and satisfying. Whether you're updating your home's aesthetics or undertaking a practical renovation, aluminum strips offer the adaptability and durability you need to bring your vision to life.

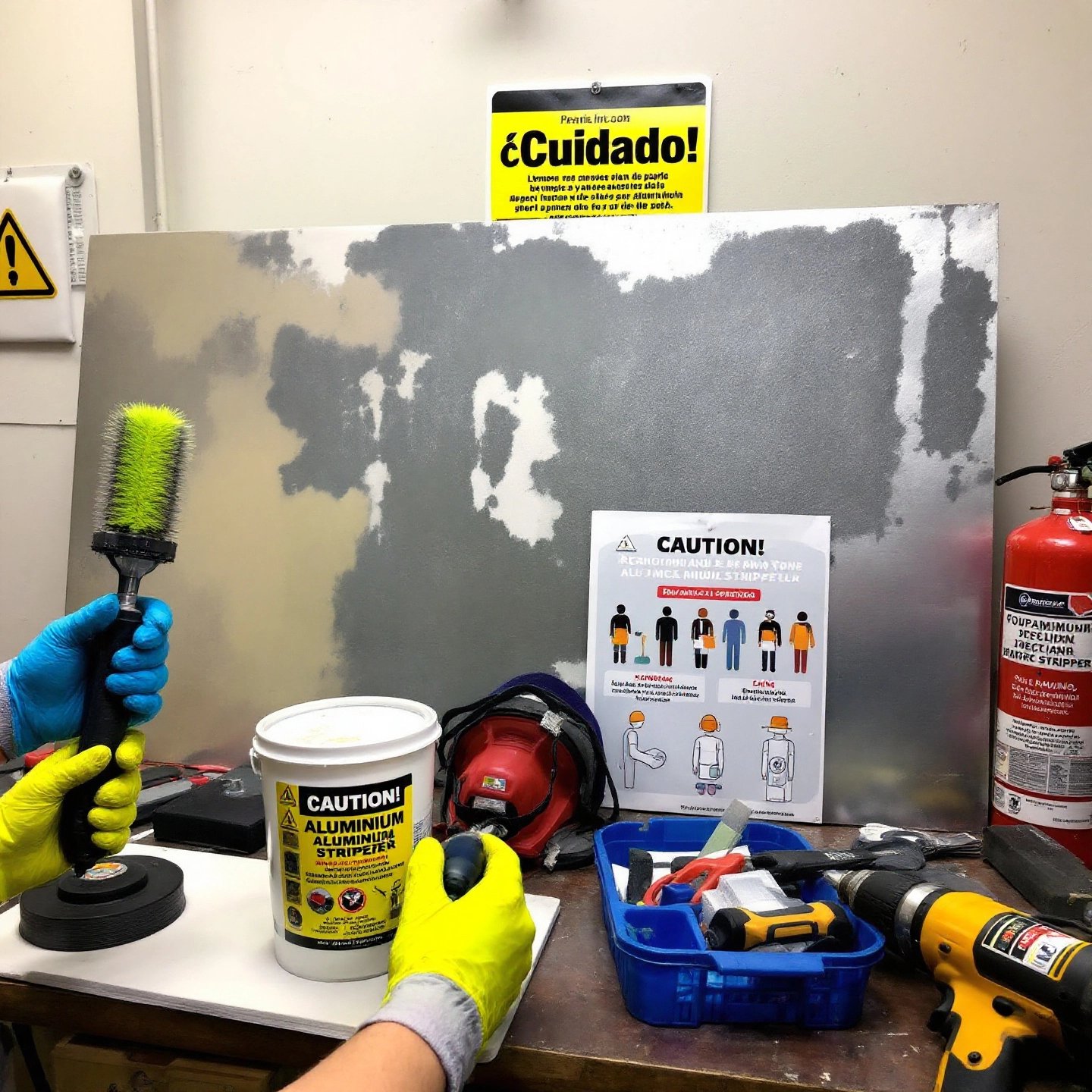

Stripping paint from aluminum surfaces can be a daunting task, especially if you're unsure where to start. With the right methods and precautions, however, it becomes a manageable DIY project. Let's explore the best ways to strip paint from aluminum, focusing on both chemical and mechanical techniques, while ensuring safety and efficiency.

Chemical paint strippers are a popular choice for removing paint from aluminum due to their effectiveness in breaking down paint bonds without damaging the metal itself. Products like General Chemical's aluminum paint strippers are designed to lift paint off the surface by dissolving the bond between the paint and the substrate. These strippers are particularly useful for intricate surfaces where mechanical methods might be too abrasive.

When using chemical strippers, it's crucial to follow the manufacturer's instructions closely. Ensure you work in a well-ventilated area and wear appropriate protective gear, such as gloves and goggles, to protect against harmful fumes and contact with the skin. It's also important to dispose of the used stripper and paint residue responsibly, as they can be hazardous to the environment.

For those who prefer a more hands-on approach, mechanical methods like sanding or using an angle grinder with a strip disk can effectively remove paint from aluminum. These techniques are best suited for flat surfaces or areas where the paint is already flaking. However, caution is necessary to avoid damaging the aluminum surface.

Using a paint scraper is another straightforward method, ideal for small projects or areas where precision is key. This tool allows for controlled paint removal, reducing the risk of scratching or gouging the metal beneath.

Regardless of the method chosen, safety should always be a priority. Proper ventilation is essential, especially when using chemical strippers or heat-based methods. If working indoors, open windows and use fans to ensure adequate airflow. Additionally, if the paint being removed is old, it may contain lead, necessitating additional precautions such as using a lead-detecting swab and opting for methods that minimize dust creation.

In conclusion, the best way to strip paint from aluminum involves selecting the appropriate method for your specific project and following safety protocols. Whether you opt for chemical or mechanical techniques, the key is to work carefully and patiently, ensuring the integrity of the aluminum is preserved while achieving a clean, paint-free surface. By doing so, you'll set the stage for a successful restoration or new finish.

When it comes to maintaining the appearance and functionality of aluminum surfaces, understanding how to effectively strip anodized layers, powder coatings, and clear coats is essential. These protective layers, while beneficial, can become worn or damaged over time, necessitating restoration to bring back the aluminum's original luster. Let's explore the techniques required for stripping and polishing aluminum surfaces, ensuring a polished finish that lasts.

Anodized aluminum is known for its durability and corrosion resistance, but it can fade or become stained, especially in harsh environments. To strip anodized aluminum, a chemical remover is often used. Products like Everbrite Coating offer solutions that can effectively remove the anodized layer while preparing the surface for re-coating. The process involves applying the remover, allowing it to penetrate, and then gently scrubbing with a non-abrasive pad to lift the anodized layer without harming the underlying metal.

Safety is paramount when using chemical removers. Always wear protective gloves and eyewear, and ensure adequate ventilation to avoid inhaling fumes. Once the anodized layer is removed, the aluminum should be thoroughly rinsed and dried before proceeding to the next steps of restoration.

Removing powder coatings and clear coats from aluminum surfaces requires a bit more effort. Mechanical methods such as sanding or using a stripping disk attached to a power tool can be effective. Start with a coarse grit to break through the coating, then gradually switch to finer grits to smooth the surface without causing damage. The goal is to remove the coating layer by layer, ensuring the aluminum surface remains intact.

For clear coat removal, chemical strippers specific to clear coat applications can be employed. These products soften the clear coat, making it easier to wipe away. As with anodized aluminum, it's crucial to follow safety protocols, including wearing protective gear and working in a well-ventilated area.

Once the old coatings are removed, polishing the aluminum is the next step. Begin by cleaning the surface to remove any debris or residue. Use a series of progressively finer sandpapers, starting around 320 grit and moving up to 600 grit or higher, to achieve a smooth surface. This process is crucial for eliminating any scratches or imperfections left by the stripping process.

After sanding, apply an aluminum polish with a clean cloth, using circular motions to buff the surface to a mirror-like finish. For added protection and to maintain the shine, consider applying a clear protective coating. Products like ProtectaClear® are designed to seal the surface, preventing oxidation and preserving the polished look for longer periods.

In summary, restoring and polishing aluminum surfaces involves careful stripping of old coatings, meticulous sanding, and applying protective finishes. By following these steps, you can rejuvenate aluminum surfaces, ensuring they remain functional and aesthetically pleasing. Whether you're working on aluminum wheels or architectural elements, these techniques provide a comprehensive approach to maintaining the integrity and appearance of aluminum.

In the realm of modern lighting design, the integration of aluminum channels with LED strip lights has emerged as a game-changer, offering both functional and aesthetic enhancements. But why are aluminum profiles so pivotal in LED lighting systems, and how do they contribute to superior performance and design?

One of the primary reasons for using an aluminum LED channel is its exceptional ability to manage heat. LED strips, while efficient, can generate significant heat, which, if not properly dissipated, can reduce their lifespan. Aluminum channels act as heat sinks, efficiently drawing away heat from the LED diodes, thereby maintaining a lower junction temperature and extending the life of the LEDs. This principle is akin to the heat sinks found in computer CPUs, ensuring that the LED strips remain cool and operate optimally over time (source) .

Beyond functionality, aluminum profiles significantly enhance the visual appeal of LED lighting. Without these channels, LED strips can appear as a series of point light sources, which may not be visually pleasing. By housing LED strips within an aluminum profile for LED strip lighting , designers can achieve a seamless, dot-free lighting effect. This is accomplished by pairing the LED strips with diffusers that scatter light evenly, creating a continuous line of illumination that is both elegant and modern (source) .

Aluminum channels come in various shapes and sizes, such as U-shaped, corner, and circular profiles, allowing for versatile applications in different settings. Whether surface-mounted, recessed, or suspended, these profiles adapt to any design requirement, making them suitable for residential, commercial, and industrial environments. The ability to customize the profile's finish and color further enhances their integration into diverse architectural styles, ensuring they complement the overall design while providing functional lighting solutions.

In conclusion, the use of aluminum channels in LED lighting systems is not merely a technical choice but a design imperative. They ensure efficient heat management, enhance the aesthetic quality of lighting, and offer versatility in application. For those looking to implement cutting-edge lighting solutions, understanding the role of aluminum profiles is essential to achieving both performance excellence and visual sophistication. As lighting technology continues to evolve, these components will remain integral to innovative design strategies, ensuring that LED systems are both beautiful and enduring.

When it comes to enhancing your home's energy efficiency, aluminum weather stripping is a simple yet effective solution. But how do you choose the right type and install it correctly to ensure maximum benefit? Let's explore the process of selecting and installing aluminum weather stripping to minimize drafts and energy loss, along with the advantages of using aluminum for this purpose.

Aluminum weather stripping is available in various forms, each designed to withstand different conditions and provide a robust seal. When selecting the right product, consider factors such as the location of the door or window, the amount of wear it will endure, and the environmental conditions it will face. For instance, commercial aluminum door weather stripping is ideal for high-traffic areas due to its durability and resistance to wear and tear (source) .

The most common types of aluminum weather stripping include tension seals, tubular rubber, and metal-backed strips. Tension seals are perfect for doors and windows that experience frequent opening and closing, as they provide a flexible yet secure fit. Tubular rubber, often paired with aluminum, offers excellent insulation against drafts and is suitable for areas exposed to moisture. Metal-backed strips, on the other hand, are highly durable and can be used in both residential and commercial settings.

Installing aluminum weather stripping is a straightforward DIY project that can significantly enhance your home's energy efficiency. Begin by measuring the dimensions of the door or window where the stripping will be applied. This ensures you purchase the correct length and minimizes waste. Once you have your materials, clean the area thoroughly to remove any dust or debris that might impede adhesion.

To install, start by cutting the aluminum strip to the appropriate size using a hacksaw for precision. Align the strip along the door or window frame, ensuring a snug fit. For metal frames, you may need to pre-drill holes to avoid damaging the material. Secure the strip with screws, leaving them slightly loose initially to allow for adjustments. Once the strip is properly aligned, tighten the screws to compress the rubber gasket against the door or window, creating a tight seal (source) .

Incorporating aluminum weather stripping into your home not only minimizes drafts but also reduces energy costs by preventing conditioned air from escaping. This is particularly beneficial in climates with extreme temperatures, where maintaining a consistent indoor environment is crucial. Additionally, aluminum's resistance to corrosion ensures longevity, making it a cost-effective investment over time.

Moreover, aluminum weather stripping can enhance the security of your home by reinforcing door and window seals, making it more difficult for intruders to force entry. Its sleek appearance also complements modern architectural designs, providing both functionality and aesthetic appeal.

In conclusion, selecting and installing aluminum weather stripping is an effective way to improve your home's energy efficiency and security. By choosing the right type and following proper installation techniques, you can enjoy a more comfortable living environment while reducing energy costs. Whether for residential or commercial applications, aluminum weather stripping offers a durable and efficient solution for sealing drafts and protecting your property.

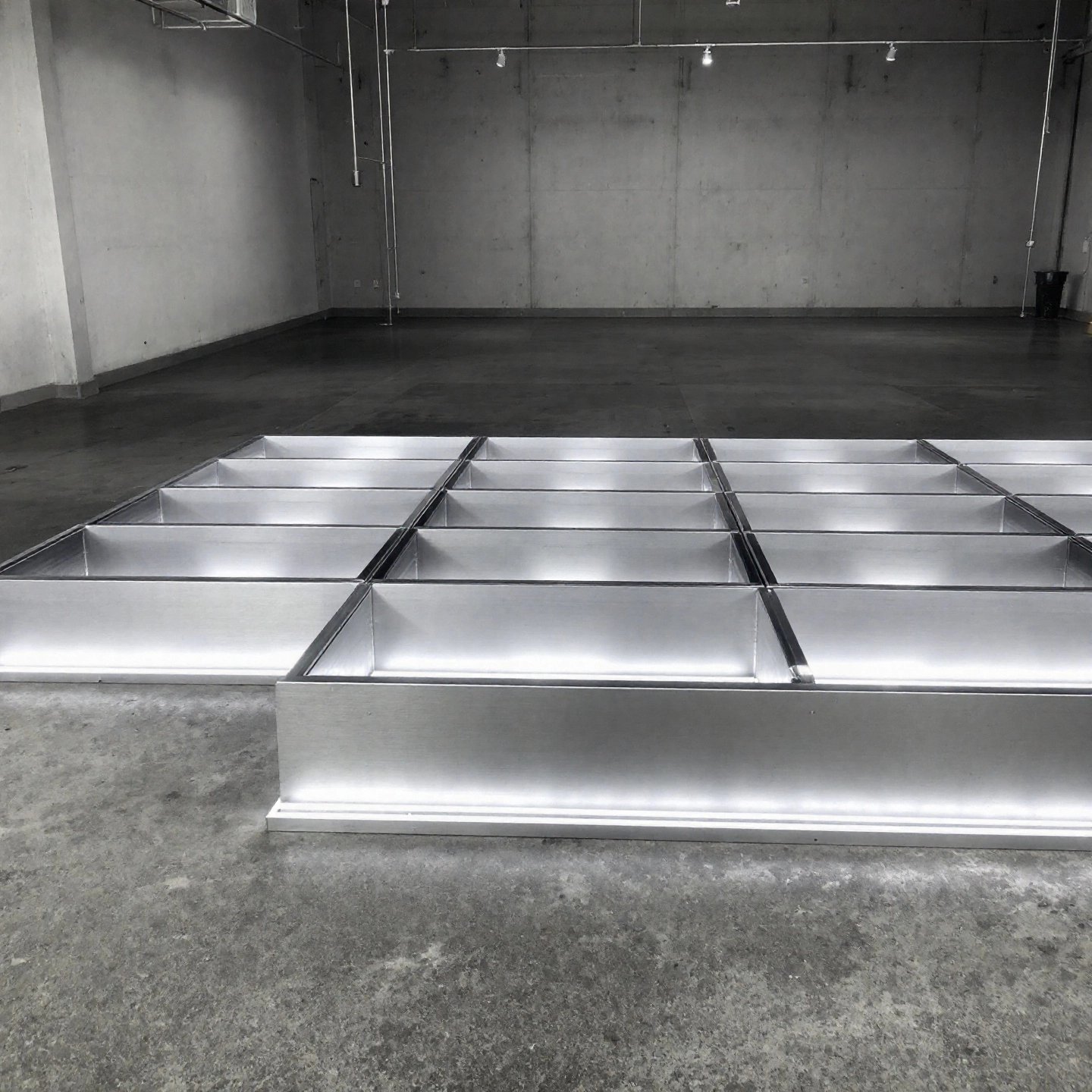

When it comes to flooring, ensuring smooth transitions between different surfaces is crucial not only for aesthetics but also for safety. Aluminum transition strips play a pivotal role in bridging uneven floors, effectively preventing trip hazards and enhancing the overall flow of your space. But how do you select the right transition solution for your flooring needs?

Aluminum transition strips are designed to create a seamless link between floors of varying heights or materials. These strips are especially useful in areas where carpet meets tile, hardwood meets laminate, or any other combination of flooring types. By providing a gentle slope, they eliminate abrupt changes in floor level, reducing the risk of trips and falls. This is particularly important in high-traffic areas such as doorways and hallways, where safety is a priority.

Moreover, aluminum transition strips are renowned for their durability and resistance to wear and tear. Made from high-strength aluminum alloys, these strips withstand heavy foot traffic and resist corrosion, making them ideal for both residential and commercial applications. Their sleek, metallic finish also adds a modern touch to any interior design, complementing a wide range of flooring styles.

In addition to floor transitions, aluminum is also extensively used in siding applications. Aluminum siding starter strips are crucial for initiating the installation of siding panels. These strips anchor the first row of siding securely to the building's structure, ensuring a straight and level base for the subsequent panels. This foundational support is essential for maintaining the integrity and appearance of the siding over time.

The use of aluminum in starter strips offers several advantages. Its resistance to rust and weathering makes it a reliable choice for outdoor applications, ensuring longevity even in harsh climates. Additionally, aluminum's lightweight nature facilitates easier handling and installation, saving time and effort during construction.

When choosing aluminum transition or starter strips, consider the specific requirements of your project. For floor transitions, assess the height difference between surfaces and select a strip that provides the appropriate slope. Products like the Trimold Aluminum Floor Transition Strip are designed to bridge gaps between 0.2 to 0.5 inches, making them versatile for various applications.

For siding projects, ensure the starter strip is compatible with the siding material being used, whether aluminum or vinyl. The 2-5/16" Mill Aluminum Starter Strip from Menards is a popular choice, offering a reliable base for siding installations.

In conclusion, aluminum transition and siding starter strips are essential components in creating safe and aesthetically pleasing environments. By selecting the right products and understanding their roles, you can ensure a seamless integration of different flooring types and a sturdy foundation for siding projects. These strips not only enhance the functionality and longevity of your installations but also contribute to a polished and professional finish.

In the rapidly evolving landscape of material science, aluminum strips are at the forefront of innovation, driven by technological advancements and sustainability imperatives. But what does the future hold for these versatile materials, and how are they shaping industries like architecture and automotive?

The future of aluminum strips is being significantly influenced by advancements in anodizing processes. These processes enhance the surface durability and aesthetic appeal of aluminum, making it a preferred choice for architectural applications. By improving corrosion resistance and UV stability, advanced anodizing techniques allow aluminum strips to maintain their appearance and structural integrity over longer periods, even in harsh environmental conditions. This makes them ideal for use in sustainable architecture, where longevity and minimal maintenance are crucial.

As environmental concerns become more pressing, the development of eco-friendly coatings for aluminum strips is gaining momentum. These coatings aim to reduce the environmental impact of aluminum production and usage by minimizing the release of volatile organic compounds (VOCs) and enhancing recyclability. Such sustainable aluminum applications are pivotal in the construction of green buildings, as they contribute to achieving higher sustainability ratings, such as LEED certifications. The ability to recycle aluminum without loss of quality further underscores its role in promoting a circular economy.

Aluminum strips are also becoming integral to the automotive industry's shift towards electric vehicles (EVs). Their lightweight nature contributes to reducing vehicle weight, thereby enhancing energy efficiency and range. Additionally, innovations in alloy compositions are improving the strength-to-weight ratio of aluminum strips, making them suitable for critical components in EVs, such as battery casings and structural parts. This not only boosts performance but also aligns with the industry's goals for sustainability and reduced emissions.

In summary, the future of aluminum strips is bright, with emerging technologies and sustainable practices driving their application across various sectors. From advanced anodizing processes that enhance durability to eco-friendly coatings that support environmental goals, aluminum strips are set to play a crucial role in shaping the future of construction and transportation. As industries continue to prioritize sustainability, the demand for innovative aluminum strip applications is only expected to grow, ensuring their relevance in a rapidly changing world.

In the diverse world of materials, aluminum strips stand out for their remarkable versatility and utility across a wide range of applications. From enhancing architectural aesthetics to contributing to the efficiency of electric vehicles, these strips are a testament to the adaptability and innovation inherent in aluminum products. But what makes them such a valuable resource in both industrial and DIY settings?

Aluminum strips offer an ideal combination of lightweight construction, superior corrosion resistance, and excellent thermal conductivity. These properties make them indispensable in projects that demand durability and efficiency, such as in aerospace, automotive, and construction industries. Imagine the possibilities: whether you're crafting intricate designs for home decor or developing cutting-edge solutions for sustainable architecture, aluminum strips provide the flexibility and strength needed to bring your vision to life.

Moreover, the market for aluminum strips is well-supported by quality manufacturers who prioritize precision and sustainability. Companies like Shengxin Aluminum exemplify this commitment, offering high-quality aluminum profiles tailored for various applications. Their advanced production capabilities ensure that each strip meets stringent standards, providing the reliability and performance that modern projects demand. By choosing manufacturers who emphasize quality and innovation, you’ll notice an enhancement in the overall success and longevity of your projects.

As we look to the future, the role of aluminum strips in sustainable development and innovative design will only continue to grow. Whether you're an industry professional or a passionate DIY enthusiast, exploring advanced materials and partnering with reputable manufacturers can significantly elevate your aluminum strips projects. Embrace the potential of this versatile material and discover how it can transform your next endeavor into a masterpiece.

Aluminum strips are versatile materials used in industries such as construction, automotive, and electronics. They are valued for their lightweight, strength, and corrosion resistance, making them suitable for structural support, decorative trims, and heat dissipation applications.

Paint can be removed from aluminum strips using chemical strippers or mechanical methods like sanding. Chemical strippers dissolve paint bonds, while sanding physically removes paint layers. Always follow safety precautions, such as working in a ventilated area and wearing protective gear.

Aluminum profiles are used in LED lighting systems for efficient heat dissipation and aesthetic enhancement. They act as heat sinks, extending LED lifespan, and provide a seamless lighting effect with the help of diffusers.

Aluminum weather stripping enhances energy efficiency by minimizing drafts and preventing energy loss. It is durable, resistant to corrosion, and complements modern architectural designs, making it ideal for both residential and commercial applications.

Emerging trends in aluminum strip applications include advanced anodizing processes for enhanced durability, eco-friendly coatings to reduce environmental impact, and integration in electric vehicles to improve efficiency and sustainability.

un service en ligne

un service en ligne 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360