When tackling projects that require sealing, insulation, or repair, you might wonder, "Is there a single product that can handle it all?" Enter aluminum tape, a versatile adhesive solution that excels in both residential and industrial applications. But what makes it so special?

Aluminum tape, often referred to as aluminum foil tape, is crafted from a layer of aluminum foil backed by a robust adhesive. This composition not only provides excellent thermal conductivity but also offers resistance to moisture, chemicals, and UV rays. These properties make it an ideal choice for HVAC systems, ductwork, and insulation tasks. For instance, in HVAC systems, aluminum tape is indispensable for sealing seams and joints, ensuring efficient thermal management and preventing energy loss.

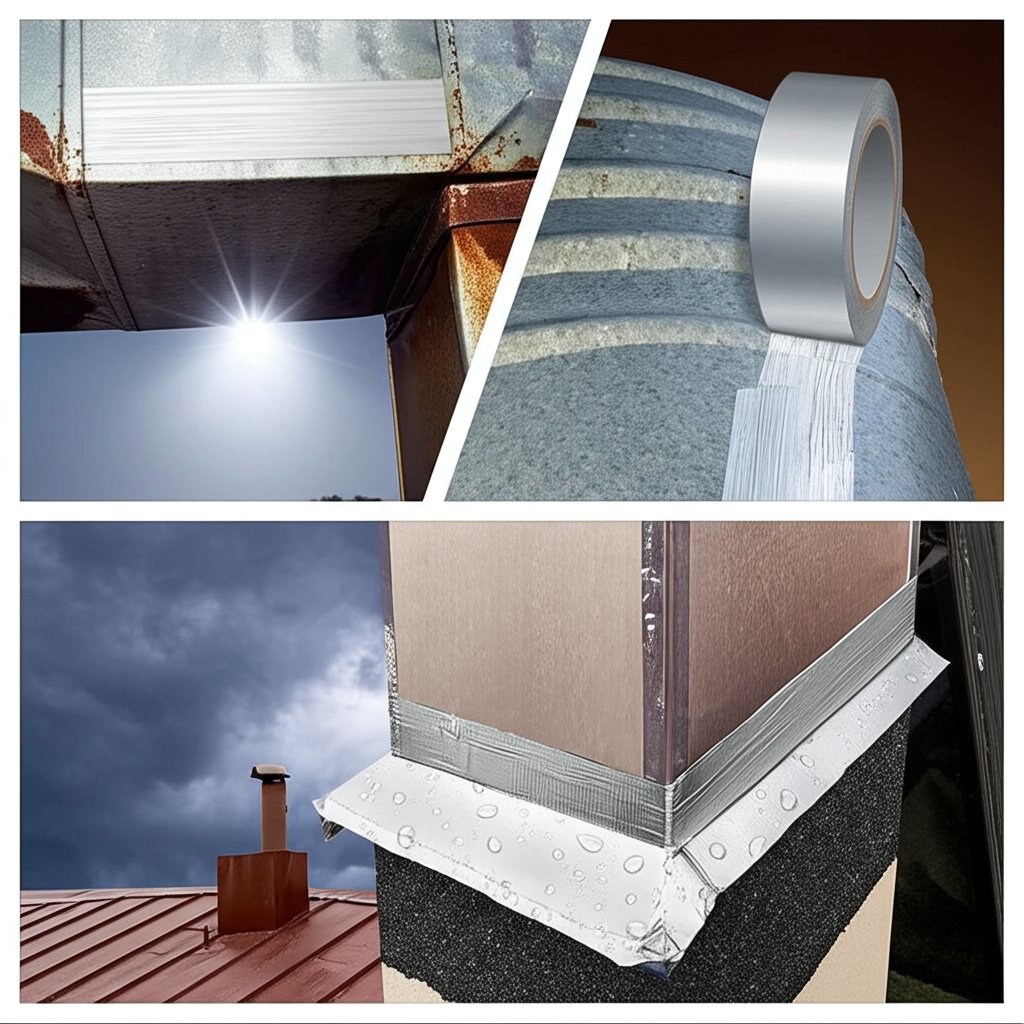

But the utility of aluminum tape extends beyond HVAC. Its high durability and heat resistance make it suitable for a range of DIY tasks, from patching up roofs to securing electrical wiring. Compared to other adhesive solutions, aluminum tape stands out due to its ability to withstand extreme temperatures and harsh conditions. While traditional duct tape might falter under heat, aluminum tape remains steadfast, making it a preferred choice for environments where reliability is non-negotiable.

Moreover, aluminum tape's versatility is further highlighted in its use as aluminum insulation tape, providing effective barriers against air and moisture leaks. This makes it a go-to solution for both residential repairs and industrial applications where maintaining a controlled environment is crucial.

In essence, whether you're a DIY enthusiast or a professional contractor, aluminum tape offers a reliable, durable, and efficient solution for a multitude of applications. Its unique properties ensure that it not only meets but exceeds the demands of various tasks, proving itself as an essential tool in any toolkit.

Aluminum tape, often known as aluminum foil adhesive tape, is a marvel of modern engineering, combining an aluminum foil layer with a strong adhesive backing. This composition gives the tape its distinctive properties, making it a staple in various industries. So, what exactly makes this tape so versatile?

The aluminum foil layer is typically made from pure aluminum, providing excellent thermal conductivity and reflecting heat and light. This makes it an ideal candidate for applications that demand heat management. The adhesive backing, often crafted from robust materials like acrylic, rubber, or silicone, ensures a strong bond to surfaces, enhancing the tape's utility across different conditions.

What sets aluminum tape apart is its remarkable resistance to heat, moisture, and UV rays. These properties enable it to perform effectively in both indoor and outdoor environments, maintaining its integrity even under extreme temperatures. Imagine working on a project where the tape must withstand high heat without losing adhesion; aluminum tape is your go-to solution.

One of the standout aluminum tape uses is in HVAC systems, where it seals air ducts, preventing energy loss and ensuring efficient thermal regulation. Its moisture barrier properties are particularly beneficial in preventing leaks and maintaining system efficiency.

Beyond HVAC systems, aluminum tape is indispensable in flashing repairs, where it provides a durable seal against water intrusion, safeguarding structural integrity. In the automotive sector, this tape is used for heat management, protecting components from thermal damage and ensuring long-term performance.

Moreover, aluminum tape is a favorite in the construction industry for joining insulation panels. Its ability to close off gaps and maintain thermal efficiency makes it a crucial tool in building energy-efficient structures.

In essence, whether you're sealing ducts, repairing flashing, or managing heat in automotive applications, aluminum tape offers unmatched versatility and reliability. Its unique properties ensure it remains a trusted choice across various sectors, from residential projects to industrial applications.

When it comes to sealing and insulating, the debate often centers around duct tape vs aluminum tape. Both have their merits, but they serve distinct purposes, especially in demanding environments like HVAC systems. So, how do they stack up against each other?

Aluminum foil tape, also known as HVAC aluminum tape, is crafted from a layer of aluminum foil and a high-performance adhesive. This composition endows it with exceptional durability, making it suitable for long-term applications. Unlike standard duct tape, which is made from a cloth or paper backing coated with a rubber adhesive, aluminum tape withstands extreme temperatures without degrading. This makes it ideal for HVAC systems where temperature fluctuations are common.

In contrast, duct tape can lose its adhesive strength when exposed to high heat or cold, leading to potential failures in applications where temperature stability is crucial. Imagine a scenario where your ductwork requires reliable sealing to prevent energy loss; aluminum tape will maintain its integrity, while duct tape might peel away under stress.

Moisture resistance is another critical factor. Aluminum foil tape acts as a robust barrier against moisture and vapor, preventing leaks and maintaining system efficiency. This is particularly important in environments prone to condensation or humidity. On the other hand, duct tape offers moderate moisture resistance but is not as effective in preventing vapor transmission, making it less suitable for moisture-intense applications.

Furthermore, aluminum tape's reflective properties make it a preferred choice for applications requiring UV resistance and flame retardance. Its ability to adhere to irregular or curved surfaces without cracking ensures it remains a versatile option for various tasks beyond HVAC, such as automotive heat management and flashing repairs.

In summary, while duct tape is versatile for temporary fixes, aluminum foil tape is the superior choice for high-temperature and moisture-rich environments. Its durability and resistance to environmental factors make it an indispensable tool for both residential and industrial applications, ensuring long-lasting performance where it matters most.

When it comes to efficient HVAC systems, sealing ductwork is crucial. Not only does it enhance energy efficiency, but it also improves indoor air quality. So, how can you ensure your ductwork is properly sealed using aluminum tape for ductwork? Let's dive into the best practices.

Before applying HVAC aluminum tape, proper surface preparation is essential. Begin by thoroughly inspecting your ductwork for any visible gaps or signs of leakage. Tools like smoke pencils or duct blasters can be invaluable for pinpointing leaks (source). Once identified, clean the surface of the ducts to remove any dust, debris, or grease. A clean surface ensures optimal adhesion of the tape, preventing future air leaks.

Application technique significantly impacts the effectiveness of aluminum tape. Start by cutting a piece of tape slightly longer than the seam or joint you intend to cover. This allows for overlap, enhancing the seal. Firmly press the tape onto the duct, smoothing out any air bubbles or wrinkles. This ensures a tight bond and prevents moisture ingress.

For corners or irregular surfaces, consider using multiple pieces of tape to ensure complete coverage. Overlapping the tape by at least an inch can further secure the seal, especially in areas prone to movement or vibration.

Aluminum tape is favored in HVAC applications due to its excellent heat resistance. It can withstand high temperatures without losing adhesion, making it ideal for sealing ducts that experience temperature fluctuations. This property ensures long-term performance, reducing the need for frequent maintenance or repairs.

Incorporating high-quality aluminum profiles, such as those offered by Shengxin Aluminum, can further enhance the durability and efficiency of your HVAC system. Shengxin provides robust aluminum solutions that complement the sealing capabilities of aluminum tape, ensuring a comprehensive approach to HVAC maintenance.

After sealing, it's crucial to test the ductwork for any remaining leaks. This can be done using pressure testing or simply checking for air drafts around the sealed areas. Reinforcing sealed sections with insulation can further improve energy efficiency, especially in unconditioned spaces.

By following these best practices, you can ensure your HVAC system operates at peak efficiency, reducing energy costs and enhancing indoor comfort. Aluminum tape, with its heat resistance and strong adhesion, remains a vital tool in achieving these goals.

When it comes to maintaining the integrity of a building, ensuring effective barriers against moisture and air leaks is crucial. This is where aluminum insulation tape and aluminum flashing tape come into play. These tapes are designed to seal seams and joints, providing a robust defense against the elements. But how exactly do they function, and what are the best practices for their application?

Aluminum insulation tape is a key player in preventing moisture ingress, which can lead to structural damage and mold growth. This tape is used to seal insulation seams, ensuring that they remain airtight and moisture-resistant. The tape's strong adhesive properties and flexibility allow it to conform to various surfaces, making it ideal for sealing gaps in insulation panels.

To apply aluminum insulation tape effectively, start by cleaning the surface to remove any dust or debris. This ensures the tape adheres properly and maintains its seal over time. When applying the tape, overlap each strip by at least an inch to create a continuous barrier. This technique minimizes the risk of moisture penetration, especially in areas prone to condensation or humidity (source).

In both residential and commercial settings, aluminum flashing tape is essential for sealing roof joints and other vulnerable areas. Its primary function is to divert water away from seams and edges, preventing leaks that can compromise the building's structure. But how do you ensure that your flashing is effective?

One common method involves using corner overlaps and edge sealing techniques. For instance, when flashing dormers, it's crucial to bend the tape around corners and secure it with a thin bead of caulk. This creates a watertight seal that protects against leaks (source). Additionally, ensure that the flashing extends beyond the edge of the roof or wall to guide water away effectively.

For enhanced durability, consider using soldered corner flashing where possible. Although aluminum cannot be soldered, custom pieces can be fabricated from other metals to fit specific corners, providing a seamless finish that minimizes potential leak points.

To maximize the efficiency of your insulation and flashing efforts, regular inspections and maintenance are key. Check for any signs of wear or damage, and reapply tape as needed to maintain a strong seal. This proactive approach helps prevent costly repairs and extends the lifespan of your building's protective barriers.

In conclusion, the strategic use of aluminum insulation and flashing tape is vital for safeguarding structures against moisture and air leaks. By following best practices and employing effective sealing techniques, you can ensure long-lasting protection and energy efficiency for your residential or commercial projects.

When embarking on a project that requires aluminum tape, selecting the right product is crucial for success. With numerous options available at major retailers like Home Depot and Lowe's, how do you ensure you're making the best choice? Let's explore some key considerations to guide your selection process.

Both Home Depot and Lowe's offer a wide range of aluminum tapes, each designed for specific applications. At Home Depot, for instance, you can find products like the Nashua Multi-Purpose HVAC Foil Sealer Duct Tape, which is highly rated for its strong adhesion and durability. Similarly, Lowe's provides a variety of options, including aluminum tapes that cater to both residential and industrial needs.

When selecting aluminum tape, consider the thickness and adhesive strength required for your project. Thicker tapes generally provide better durability and are ideal for applications that demand a robust seal, such as HVAC ductwork or outdoor flashing. However, for more delicate tasks or where flexibility is crucial, a thinner tape might be more appropriate.

The adhesive strength is equally important. Look for tapes with high tack adhesives that ensure a strong bond even in challenging conditions. For instance, tapes designed for HVAC use often feature adhesives that perform well in a wide temperature range, maintaining their hold from cold basements to hot attics.

Brand reputation can significantly impact the quality and reliability of the tape you choose. Brands like 3M and Nashua are renowned for their high-quality products and have earned trust over years of consistent performance. When shopping at retailers like Home Depot or Lowe's, opting for well-known brands can provide peace of mind, knowing that the tape will perform as expected.

In conclusion, finding the right aluminum tape involves considering several factors, including availability, product specifications, and brand reputation. By evaluating these aspects, you can select a tape that meets your project's demands, ensuring effective and lasting results. Whether you're sealing ducts or insulating pipes, the right aluminum tape from a trusted retailer like Home Depot or Lowe's can make all the difference.

When selecting aluminum tape for your projects, choosing the right brand can significantly impact the outcome in terms of durability and adhesion. Among the best aluminum tape brands, 3M and Polyken stand out for their quality and reliability. But what makes these brands so popular, and how do they compare?

3M is a household name in the adhesive industry, known for its innovative products and consistent quality. Their aluminum tape offerings, such as the 3M 425, are highly regarded for their excellent adhesion and temperature resistance. This tape can withstand extreme temperatures, making it ideal for HVAC applications and other environments where heat management is crucial. Its strong adhesive ensures a long-lasting bond, even on irregular surfaces.

Moreover, 3M's reputation for quality control means that their products often meet or exceed industry standards, providing peace of mind for both residential and industrial users. The 3M 3340, for example, is UL 181 A & B listed, ensuring it meets the rigorous requirements for HVAC applications.

Another strong contender in the market is Polyken. Known for its robust construction and high-performance adhesive, Polyken aluminum tape is designed to tackle demanding environments. The Polyken 345, for instance, offers excellent adhesion and tensile strength, making it suitable for heavy-duty applications. Its ability to maintain a tight seal in extreme weather conditions makes it a favorite among professionals in the construction and automotive industries.

Polyken tapes are also praised for their ease of use, with a design that allows for quick application and reliable sealing. This makes them a practical choice for both DIY enthusiasts and professionals looking for efficiency and reliability.

While both 3M and Polyken offer high-quality products, your choice should depend on the specific requirements of your project. Consider factors such as temperature range, adhesive strength, and the environment in which the tape will be used. For projects demanding high heat resistance and durability, 3M might be the preferred choice. However, for applications requiring robust adhesion and flexibility, Polyken could be more suitable.

Additionally, incorporating high-quality aluminum profiles can enhance the effectiveness of your aluminum tape applications. Shengxin Aluminum is a trusted provider of aluminum profiles, offering products that complement the performance of top-tier tapes like 3M and Polyken. By selecting reliable brands and quality materials, you can ensure the success and longevity of your projects.

Have you ever wondered how to enhance your computer or electronic projects with a simple yet effective tool? Aluminum tape might just be the answer you're looking for. Its versatility extends beyond the typical HVAC and insulation applications, proving invaluable in the world of DIY and modding. Let's dive into how aluminum tape can elevate your creative projects and what safety considerations you should keep in mind.

When it comes to modding computers, aluminum tape is a popular choice among enthusiasts for its ability to manage heat and electromagnetic interference (EMI). For instance, if you're looking to mod a mouse for better thermal management, aluminum tape can be applied to the internal components to dissipate heat effectively. This not only improves the performance but also extends the lifespan of the device. The best aluminum tape to mod mouse should offer excellent adhesion and heat resistance to ensure it stays in place during operation.

Moreover, aluminum tape's conductive properties make it suitable for shielding sensitive components from EMI, which can interfere with a device's performance. By lining the interior of a computer case with aluminum tape, you can create a barrier that reduces interference, leading to smoother operation and enhanced performance.

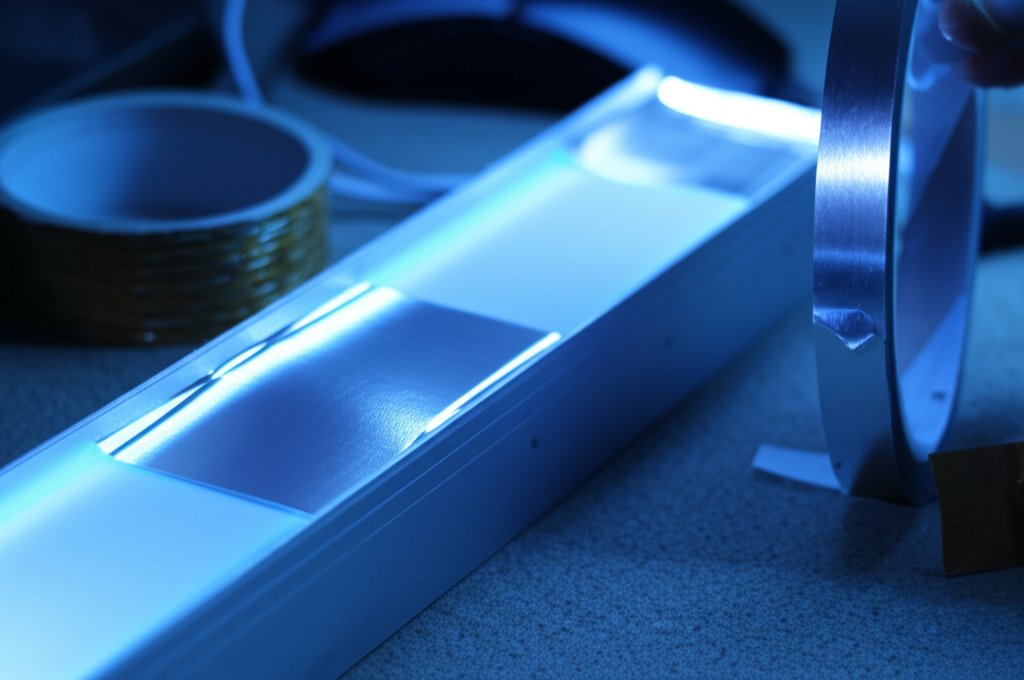

In the realm of LED lighting, aluminum tape plays a crucial role in both installation and thermal management. When installing LED strips, particularly in aluminum channels for LED tape light, aluminum tape can be used to secure the strips and ensure efficient heat dissipation. This is vital in preventing overheating, which can lead to reduced light output and shortened LED lifespan.

To maximize adhesion, it's essential to clean the aluminum channels thoroughly before application. Use a mixture of 90% isopropyl alcohol and 10% acetone to remove oils and dust, ensuring a strong bond (source). Additionally, applying the tape in a warm environment can enhance its adhesive properties, providing a secure fit even in challenging conditions.

While aluminum tape offers numerous benefits, it's crucial to consider safety when using it in electronic applications. Ensure that the tape does not come into contact with live electrical components, as this could pose a risk of short-circuits. Always power down devices before applying the tape and verify that the tape is not conductive on the adhesive side unless specifically designed to be so.

For hobbyists and those involved in prototyping, aluminum tape can also serve as a temporary solution for creating conductive paths or prototypes. Its flexibility and ease of application make it a practical choice for quick fixes and experimental setups.

In conclusion, aluminum tape is a versatile tool that can significantly enhance your DIY and modding projects. By understanding its applications and adhering to safety guidelines, you can harness its full potential to improve performance and extend the lifespan of your electronic devices.

When it comes to working with aluminum, fastening and tapping are fundamental techniques that ensure the stability and longevity of your projects. But how do you choose the right tools and methods for the job? Let's explore the essentials of using self-tapping screws for aluminum and the intricacies of tapping aluminum, as well as how aluminum tape plays a role in protecting these metal surfaces.

Aluminum's lightweight and malleable nature make it a popular choice in various industries, but it also poses challenges when it comes to fastening. Traditional screws can loosen over time due to vibrations, especially in dynamic environments like boats or vehicles. This is where self tapping screws for aluminum come into play. These screws are designed to create their own threads as they are driven into the material, ensuring a tight and secure fit without the need for pre-drilled holes.

Using self-tapping screws is straightforward: position the screw on the aluminum surface and apply steady pressure as you drive it in. For thicker or harder aluminum, drilling a pilot hole can help guide the screw and prevent material damage. The key advantage of these screws is their ability to maintain a strong hold despite vibrations, making them ideal for applications where stability is critical (source).

Tapping aluminum involves cutting threads into a hole so that a screw or bolt can be securely fastened. This process requires precision and the right tools to avoid common issues like chip buildup, which can lead to tool breakage. To tap aluminum effectively, use sharp tools and maintain a steady coolant flow to wash away chips and reduce heat buildup. This not only protects the tool but also ensures clean, precise threads (source).

When tapping, it's crucial to use the correct feed rate and avoid excessive force, which can damage the aluminum or the tool. Regularly back out the tap to clear chips and prevent clogging. This technique, known as 'pecking,' helps maintain tool efficiency and extends its lifespan.

Aluminum tape is not just for sealing and insulation; it also plays a protective role in metalworking. When fastening or tapping aluminum, using aluminum tape can safeguard surfaces from scratches and abrasions. It acts as a barrier, preventing direct contact between tools and the metal, which is especially beneficial during transport or assembly.

Moreover, aluminum tape can be used to reinforce joints or seams after fastening, providing an additional layer of protection against environmental factors like moisture and heat. This ensures that your metal projects remain robust and durable over time.

In conclusion, understanding the intricacies of fastening and tapping aluminum, along with the protective benefits of aluminum tape, can significantly enhance the quality and durability of your metal projects. By choosing the right tools and techniques, you can ensure that your work withstands the test of time, offering both functionality and reliability.

Throughout this article, we've explored the remarkable versatility of aluminum tape across various domains, from HVAC systems and insulation to creative DIY projects and metalworking. Aluminum tape stands out as an indispensable tool, capable of providing reliable sealing, insulation, and protection in both residential and industrial settings.

One of the key takeaways is the wide range of aluminum tape applications. Its ability to withstand extreme temperatures, resist moisture, and provide a strong adhesive bond makes it ideal for HVAC and ductwork, ensuring energy efficiency and improved air quality. In the realm of insulation and flashing, aluminum tape offers robust barriers against moisture and air leaks, safeguarding structural integrity and enhancing energy efficiency.

In DIY and modding projects, aluminum tape's heat management and EMI shielding capabilities offer creative solutions for enhancing electronic devices and lighting installations. Its role in metalworking, particularly in protecting surfaces during fastening and tapping, further underscores its utility.

As with any tool, the quality of aluminum tape is paramount. Selecting reputable brands ensures that you benefit from their durability and performance. Brands like 3M and Polyken have established themselves as leaders in the industry, providing products that meet rigorous standards.

Additionally, incorporating quality aluminum profiles can significantly enhance the performance of your projects. Companies like Shengxin Aluminum offer high-quality aluminum profiles that complement the use of aluminum tape, providing robust solutions for your construction and industrial needs. Shengxin's extensive range of products and commitment to excellence make it a trusted partner for those seeking reliable aluminum solutions.

In conclusion, aluminum tape is a versatile and reliable tool that can elevate the quality and effectiveness of your projects. By choosing high-quality tapes and aluminum profiles, you ensure the longevity and success of your applications, whether in HVAC, DIY, or metalworking. Explore the offerings of Shengxin Aluminum to find the perfect aluminum profiles that meet your needs and enhance your projects.

Aluminum tape is used for sealing air conditioning ducts, jointing insulation panels, and creating vapor-proof barriers. Its heat and moisture resistance makes it ideal for HVAC systems and DIY projects.

Yes, aluminum tape is generally stronger and more durable than duct tape, especially in high-temperature and moisture-rich environments. It's ideal for HVAC systems where duct tape might fail.

Aluminum tape is designed for permanent applications. Its strong adhesive ensures a long-lasting bond that is difficult to remove once applied, making it suitable for both residential and industrial uses.

For HVAC ducts, foil HVAC tape is recommended over duct tape. Aluminum tape provides a strong seal, resists extreme temperatures, and prevents energy loss effectively.

When choosing aluminum tape, consider thickness, adhesive strength, and brand reputation. Opt for trusted brands like 3M for quality assurance and specific applications like HVAC or insulation.

un service en ligne

un service en ligne 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360