When you pick up a soda can or wrap leftovers in foil, you might wonder: is aluminum magnetic? Or, more specifically, will a magnet stick to aluminum? The answer isn’t as simple as a yes or no, but let’s break it down clearly.

Aluminum is not magnetic in the way you might expect from metals like iron or steel. If you try to stick a magnet to a piece of aluminum—whether it’s a can, a sheet, or foil—it simply won’t cling. This is why people often say aluminium non magnetic. But why?

Aluminum belongs to a class of materials known as paramagnetic. Unlike ferromagnetic metals (like iron, nickel, or cobalt), which have strong, permanent magnetic properties, paramagnetic materials have only a very weak attraction to magnets. In fact, this attraction is so faint that you won’t notice it in everyday life. So, if you’re asking, “do magnets stick on aluminum?” the practical answer is no—they don’t.

While aluminum is technically a paramagnetic metal, its magnetic attraction is so weak that, for all practical purposes, it is considered non-magnetic. Magnets will not stick to aluminum under normal conditions.

In summary, is aluminum a magnetic metal? Technically, it has a mild, temporary response to very strong magnetic fields, but this effect is invisible in daily scenarios. For most uses, aluminum is a magnetic metal only in the scientific sense—and not in the way that matters for your fridge magnets or household projects.

Have you ever wondered why a fridge magnet snaps onto an iron pan but slides right off an aluminum can? The answer lies deep within the tiny building blocks of these metals—their atoms and electrons. To truly understand why isn't aluminum magnetic, let’s break down the science in simple terms.

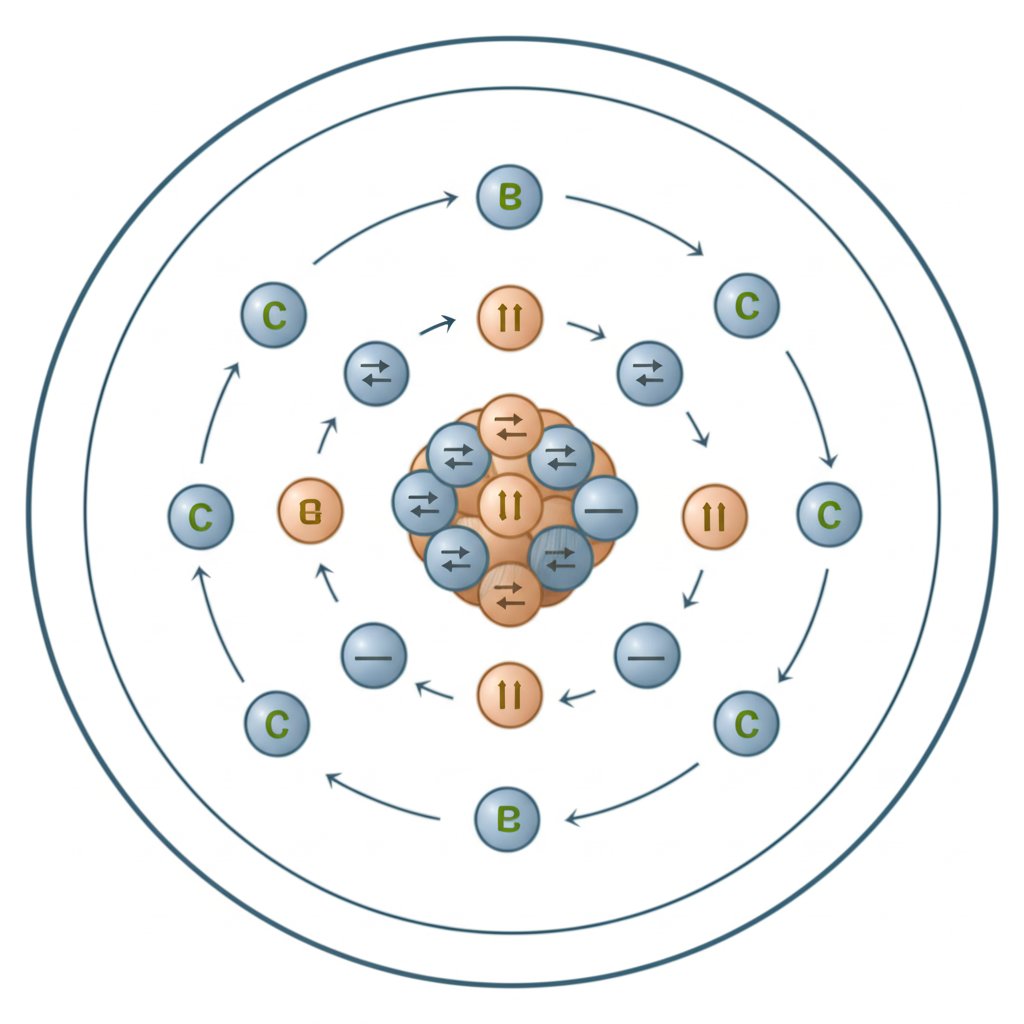

First, let’s talk about what makes something magnetic in the first place. Magnetism in metals is all about the behavior of electrons—those tiny, negatively charged particles that spin around the nucleus of every atom. When electrons spin in a certain way and are left unpaired, they can create strong magnetic fields. If many of these unpaired electrons line up in a material, the result is a powerful, permanent magnet. This is what happens in metals like iron, which are called ferromagnetic materials.

But aluminum is different. Even though it’s a metal, its atomic structure and electron configuration don’t allow for the same kind of unpaired electron alignment. Imagine electrons as tiny dancers: in iron, many of these dancers are solo, spinning freely and forming groups (magnetic domains) that all point in the same direction. In aluminum, almost all the dancers are paired up, spinning in opposite directions—so their movements cancel each other out. That’s why aluminum is not ferromagnetic.

So, why is aluminium not magnetic? It’s because its atomic structure doesn’t support the formation of strong, aligned magnetic domains. The few unpaired electrons in aluminum don’t stay unpaired in the solid state—they pair up with electrons from other atoms, wiping out the chance to create a noticeable magnetic field (source).

To put it another way, is aluminum ferromagnetic? No. It’s classified as paramagnetic, meaning it shows only a very weak, temporary attraction to strong magnetic fields. This is so faint that you’ll never notice it in daily life, and will aluminum stick to a magnet? Absolutely not—at least, not in any way you’d see or feel.

Curious if are all metals magnetic? The answer is no. Magnetism depends on the arrangement of electrons and the type of element. While iron, nickel, and cobalt are strongly magnetic, metals like aluminum, copper, and gold are not. Each element’s unique electron configuration determines which element is magnetic and which ones aren’t.

Now that you know the science behind aluminum’s non-magnetic nature, let’s explore what happens when aluminum does interact with magnets—even if it’s not in the way you might expect.

Sounds complex? Let’s break it down. When you bring a magnet near a piece of aluminum, you’ll notice—well, nothing. There’s no dramatic snap, no sticking, and no visible reaction. But beneath the surface, something subtle is happening. Aluminum is classified as a paramagnetic material. That means it has a very weak and temporary attraction to strong magnetic fields. This is a far cry from the strong pull you’d see with iron or nickel, but it’s a fascinating property that sets aluminum apart from other metals.

So, what exactly does paramagnetism mean for aluminum magnetic properties? In simple terms, the atoms in aluminum have unpaired electrons that can align very slightly with an external magnetic field. This alignment is so minimal that you’d need specialized scientific instruments to detect it—certainly nothing you’d see with the naked eye or feel with a household magnet. In fact, the effect is millions of times weaker than the magnetism you experience with ferromagnetic materials.

Paramagnetism is a form of magnetism whereby certain materials are weakly attracted by an externally applied magnetic field, and form induced magnetic fields in the direction of the applied magnetic field. In aluminum, this effect is so faint that it is practically undetectable in everyday life.

Why does this matter? For most people, it simply means that aluminum won’t interfere with electronics, navigation systems, or sensitive instruments. For engineers and designers, understanding aluminium magnetic properties and aluminium permeability is crucial for selecting the right material for applications where even the slightest magnetic response could cause problems—think MRI machines, aerospace components, and high-frequency electronics.

If you’re curious to dive deeper into the science and myths behind aluminum’s magnetic behavior, check out this related blog: Is Aluminum Magnetic? Unveiling the Science and Myths.

Now that you know why aluminum’s paramagnetism is almost invisible in daily life, let’s explore what really happens when you move a strong magnet near aluminum—and why that interaction is more surprising than you might expect.

When you first learn that aluminum is non-magnetic, you might assume it’s completely unaffected by magnets. But what if you move a strong magnet quickly past an aluminum can or sheet? You might be surprised to find that the magnet seems to slow down, or even feels like it’s being pushed away. What’s happening here isn’t ordinary magnetism—it's the fascinating phenomenon of eddy currents.

So, do magnets stick to aluminum? No, they don’t. But under the right conditions, magnets and aluminum can interact in ways that defy our everyday expectations. This effect isn’t about magnets sticking—it's about motion, electricity, and invisible forces at play.

Let’s break it down: When a strong magnet moves near aluminum, it creates a changing magnetic field. This shifting field pushes electrons inside the aluminum into circular paths—these are called eddy currents. Even though aluminum isn’t magnetic in the traditional sense, it’s an excellent conductor of electricity, so these currents form easily.

Here’s the key: The eddy currents themselves generate their own magnetic field, which acts in the opposite direction of the original magnet’s field. This opposition creates a noticeable force—almost like a magnetic brake—that slows down the magnet or resists its movement. That’s why, if you drop a strong magnet through an aluminum tube, it falls much more slowly than it would through air or a plastic tube. The magnet and the aluminum never "stick," but their interaction is anything but boring.

When a magnet moves near aluminum, it induces swirling electrical currents—eddy currents—which generate a magnetic field that opposes the motion of the magnet, resulting in a visible braking or repulsive effect.

This effect is not unique to aluminum, but because aluminum is both non-magnetic and a good electrical conductor, it’s especially pronounced. That’s why you’ll see this phenomenon in science museums or physics demonstrations using aluminum tracks or tubes (source).

Curious to see eddy currents in action? Here’s a simple experiment you can do at home using everyday items:

This simple "foil magnet" experiment is a hands-on way to experience eddy currents. It shows that while magnets sticking to aluminum won’t happen, there’s still a fascinating interaction between the two.

In summary, will magnets stick to aluminum? No. Aluminum remains non-magnetic, so ordinary magnets won’t cling to it. But when you introduce motion, you unlock a new world of physics where electricity and magnetism dance together. This is why you might see aluminum used in applications like electromagnetic braking systems and induction cooktops—places where its unique response to changing magnetic fields is an asset, not a drawback.

Next, we’ll compare aluminum’s magnetic behavior to other common metals, so you can see exactly where it fits in the world of magnetism.

When you’re sorting through a box of hardware or choosing materials for a project, you might wonder: which metals are not magnetic, and how does aluminum fit into the bigger picture? Understanding the magnetic properties of various metals can help you make better choices—whether you’re designing electronics, building machinery, or simply curious about why some objects stick to magnets and others don’t.

Let’s break down the key differences between common metals by comparing their magnetic types, everyday responses to magnets, and unique characteristics. This context will help clarify why steel or aluminum behave so differently around magnets, and why you’ll never see a fridge magnet sticking to a copper pipe or a titanium bolt.

| Metal | Magnetic Type | Everyday Magnetic Response | Key Characteristic |

|---|---|---|---|

| Aluminum | Paramagnetic | Not attracted to magnets; no visible effect | Lightweight, corrosion-resistant, what metals are not magnetic |

| Steel (Carbon) | Ferromagnetic | Strongly attracted to magnets; can be magnetized | High strength, widely used; is steel a magnetic material |

| Stainless Steel (Austenitic) | Paramagnetic (mostly) | Not attracted to magnets in most cases | Excellent corrosion resistance; used in medical and food industries |

| Copper | Diamagnetic | Very weakly repelled by magnets; no attraction | Excellent electrical conductor; classic example of magnetic non magnetic metals |

| Titanium | Paramagnetic | No noticeable attraction to magnets | Lightweight, strong, biocompatible; will a magnet stick to titanium? No |

As you can see, which metals are not magnetic? Most non-ferromagnetic metals—including aluminum, copper, tin, and titanium—show little to no attraction to magnets. Only iron, most carbon steels, and certain stainless steels (notably ferritic and martensitic types) are truly magnetic in daily life.

Understanding these differences helps you select the right material for your needs—whether you’re choosing between steel or aluminum for a structural project, or making sure your hardware won’t interfere with sensitive electronics. Next, we’ll clear up some common myths and misconceptions about aluminum and magnetism—so you’ll always know what to expect the next time you grab a magnet.

When you see a shiny aluminum can or a sheet of foil, you might wonder: is aluminium magnetic material? Or maybe you’ve heard someone claim that can magnets stick to aluminum if it’s a certain type, like anodized or foil. With so many mixed messages, it’s easy to get confused. Let’s set the record straight by busting some of the most common myths about aluminum and magnetism.

Many of these misconceptions come from the fact that aluminum is a metal, and people often assume all metals behave the same way around magnets. In reality, the atomic structure of each metal dictates its magnetic behavior. Aluminum’s electrons are paired up in such a way that, even as a pure metal or in the form of foil, it cannot develop strong magnetic domains.

Whether you’re recycling cans, using foil in the kitchen, or working with anodized aluminum parts, you can be confident that magnets won’t stick. If you ever need to test whether a piece of metal is aluminum, try a magnet—if it doesn’t stick, there’s a good chance it’s aluminum (though some stainless steels are also non-magnetic).

Now that you know the truth behind these common myths, you’ll be able to spot misinformation and make better choices when working with or selecting materials. In the next section, we’ll look at how certain factors—like alloys and temperature—can subtly influence aluminum’s properties, and whether any exceptions exist to its famously non-magnetic nature.

Ever wondered if there are exceptions to the rule that aluminum isn’t magnetic? Or maybe you’ve picked up an aluminum washer and asked yourself, "is aluminum washer magnetic?" Let’s dig into how real-world factors like alloying and temperature can subtly shift the magnetic behavior of aluminum—and what that means for you.

Pure aluminum is paramagnetic, meaning it has only a faint, temporary attraction to strong magnetic fields. But what happens when you mix it with other metals? In the real world, most aluminum products aren’t made from pure aluminum—they’re alloys, created by blending aluminum with elements like copper, magnesium, silicon, iron, or nickel to improve strength, durability, or corrosion resistance.

Here’s the key: If an aluminum alloy contains significant amounts of ferromagnetic elements, such as iron or nickel, it can show a slight magnetic response. This is most noticeable in alloys with higher iron content, where you might detect a weak attraction with a strong magnet. However, even in these cases, the effect is minimal compared to true ferromagnetic metals like steel. For example, if you’re testing an aluminum washer or fastener and a magnet seems to stick—chances are, it contains enough iron to create a detectable response. Still, most common aluminum alloys remain non-magnetic for practical purposes.

Temperature can have a big effect on magnetism in many materials. For example, heating iron past a certain point (the Curie temperature) destroys its magnetism. But what about aluminum?

For paramagnetic metals like aluminum, extreme heat can actually reduce their already weak magnetic response. When exposed to high temperatures, the random motion of atoms increases, making it even harder for their electrons to align with an external magnetic field. In practice, this means aluminum’s faint paramagnetism becomes even less noticeable when heated—but since it’s already so weak, you’ll never see a practical difference outside of a laboratory.

Sometimes, the concern isn’t about magnetism at all, but about what happens when aluminum and other metals—like stainless steel—are used together. This brings up the topic of the stainless steel and aluminium reaction. When these two metals come into direct contact in the presence of moisture (especially in salty environments), they can undergo galvanic corrosion. This reaction doesn’t affect magnetism, but it can impact the longevity and safety of your project. Using insulating washers or coatings is the best way to prevent this type of corrosion when combining these metals.

In summary, while pure aluminum remains non-magnetic in almost every situation, certain alloys and environmental factors can introduce minor exceptions. For most practical uses, though, you’ll find that aluminum’s reputation for being non-magnetic holds true. Next, let’s explore why this property is so valuable in advanced technology and manufacturing.

Imagine building an airplane, a high-speed train, or the next generation of electronics—would you want a material that could disrupt delicate sensors or navigation systems? This is where aluminum’s non-magnetic nature truly shines. While most people know that is aluminium magnetic is a common question, the answer has far-reaching consequences in advanced industries far beyond the kitchen or recycling bin.

In all these industries, it’s not enough for aluminum to be simply non-magnetic. The purity of the metal and the exact alloy composition must be tightly controlled. Even trace amounts of ferromagnetic elements can compromise performance in precision applications. For example, in aerospace or high-frequency electronics, the wrong alloy could introduce minute magnetic responses or fail to meet stringent safety standards.

So, does magnet stick to aluminum in these high-tech settings? Absolutely not—if the right grade is used. That’s why engineers and manufacturers turn to trusted suppliers who can guarantee both non-magnetic properties and the mechanical strength needed for demanding environments.

For projects where the stakes are high—whether you’re designing maglev tracks, constructing aircraft, or building advanced electronics—selecting the right aluminum profile is non-negotiable. Sourcing non magnetic aluminum with precise specifications is essential to ensure both safety and performance.

This is where working with a specialized manufacturer makes all the difference. Shengxin, a professional aluminum profile manufacturer based in China, stands out for its expertise in producing high-purity, custom alloy aluminum products. Shengxin’s advanced production capabilities and strict quality controls mean you get materials tailored for critical industries—whether you need lightweight structural profiles for aerospace, EMI-shielding enclosures for electronics, or high-performance aluminium magnet wire for specialized coils and motors.

In summary, the answer to is aluminium magnetic is more than a scientific curiosity—it’s a foundation for modern technology. When failure isn’t an option, and performance is everything, the right material—and the right supplier—make all the difference. For high-stakes projects, always insist on certified, high-quality aluminum profiles from a trusted expert like Shengxin.

No, a magnet will not stick to aluminum. Aluminum is classified as a paramagnetic material, which means its attraction to magnets is extremely weak and unnoticeable in everyday situations. Magnets only stick to ferromagnetic materials like iron or steel.

Aluminum's atomic structure causes its electrons to pair up, preventing the formation of strong magnetic domains. This means aluminum cannot develop a noticeable magnetic field and is regarded as non-magnetic for all practical purposes.

While aluminum is not magnetic, it can interact with magnets through the phenomenon of eddy currents. When a strong magnet moves near aluminum, it induces electrical currents in the metal that create a temporary opposing magnetic field, resulting in a noticeable braking or repulsive effect.

Most aluminum alloys remain non-magnetic. However, if an alloy contains significant amounts of ferromagnetic elements like iron or nickel, it may show a very slight magnetic response. For most applications, aluminum and its common alloys are considered non-magnetic.

Non-magnetic aluminum is essential in industries like aerospace, electronics, and high-speed rail because it prevents magnetic interference with sensitive equipment and allows for safe, reliable operation. High-purity aluminum profiles are especially crucial in these advanced applications.

un service en ligne

un service en ligne 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360